Printed Circuit Boards (PCBs) are at the heart of modern electronics—but as devices become smaller, more powerful, and more widely used in harsh environments, protecting these sensitive components has become more critical than ever. That’s where conformal coating in PCB protection steps in as a game-changer.

Whether it’s a consumer product exposed to daily wear or a military-grade device deployed in extreme climates, PCBs need an added layer of protection. Conformal coating provides exactly that: a thin, durable film that safeguards electronics from moisture, dust, chemicals, and temperature extremes without compromising performance or size.

What Is Conformal Coating?

What Is Conformal Coating?

![]()

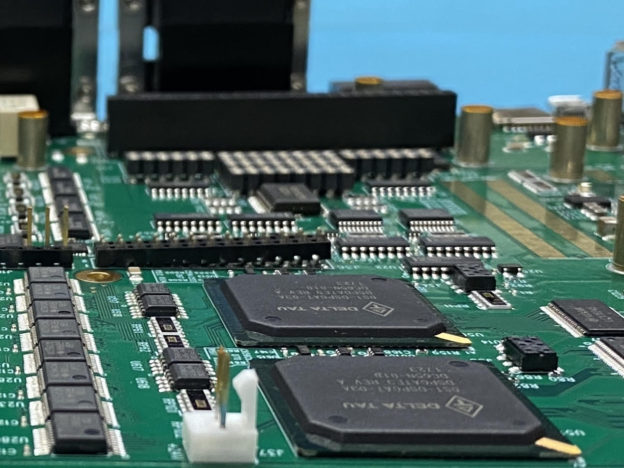

![]() Conformal coating is a protective chemical layer applied to the surface of a PCB to create a barrier against environmental contaminants. It’s “conformal” because it conforms to the shape of the board and its components, coating even hard-to-reach areas without needing bulky enclosures.

Conformal coating is a protective chemical layer applied to the surface of a PCB to create a barrier against environmental contaminants. It’s “conformal” because it conforms to the shape of the board and its components, coating even hard-to-reach areas without needing bulky enclosures.

At Board Assembly, we apply conformal coatings using precise, industry-approved techniques that ensure full coverage without interfering with the function or accessibility of electronic parts.

Why Is Conformal Coating Becoming More Important?

As electronics continue to expand into sectors like automotive, aerospace, defense, and IoT devices, the environments these PCBs operate in are becoming more unpredictable and challenging.

Here are a few key reasons conformal coating is gaining traction:

-

Moisture & Corrosion Resistance: In humid or marine environments, moisture can cause corrosion, short-circuits, and long-term failure. Conformal coatings seal off the PCB surface, keeping moisture at bay.

-

Chemical Protection: In industrial settings, exposure to cleaning agents, fuels, or harsh chemicals is common. A conformal coating acts as a shield, preventing chemical damage.

-

Dust & Debris Protection: For electronics in outdoor or manufacturing environments, dust accumulation can hinder performance. Coatings protect against particulate buildup.

-

Extended Product Life: By protecting the PCB from environmental damage, conformal coatings significantly increase product reliability and longevity—essential for industries where equipment failure is not an option.

Applications Across Industries

From automotive control units to aerospace avionics, and from wearable medical devices to outdoor smart home systems, conformal coating in PCB protection is now a standard best practice in many industries. As miniaturization and high-performance demands increase, protective coatings are no longer optional—they’re essential.

Why Work With Board Assembly?

At Board Assembly, we offer advanced PCB assembly solutions that include precision-applied conformal coatings to ensure your product performs reliably in any environment. Whether you need protection from moisture, vibration, chemicals, or dust, our team ensures your PCB is ready for real-world conditions.

Want to learn more about how conformal coating can improve your product’s performance and durability? Contact us today to discuss your PCB protection needs.

Flexible PCB Assembly for Every Project Size

Flexible PCB Assembly for Every Project Size

The

The  Adding the silkscreen is typically the final step in PCB fabrication, done while the boards are still panelized. The ink used must be carefully chosen to withstand the chemicals and heat involved in soldering and assembly. Once printed, the board moves to the final finishing or routing phase.

Adding the silkscreen is typically the final step in PCB fabrication, done while the boards are still panelized. The ink used must be carefully chosen to withstand the chemicals and heat involved in soldering and assembly. Once printed, the board moves to the final finishing or routing phase. Trust ACME PCB for Quality PCB Manufacturing

Trust ACME PCB for Quality PCB Manufacturing

A box build (also known as system integration or

A box build (also known as system integration or  While

While

ACME PCB Assembly

ACME PCB Assembly