There Are Differences Between Printed Circuit Board Manufacturing and Printed Circuit Board Assembly, But You Might Be Asking What Are They?

In the world of electronics, the terms Printed Circuit Board (PCB) Manufacturing and PCB Assembly are often used interchangeably—but they actually refer to two distinct processes. Understanding the difference is essential when choosing the right partner for your electronic product development.

At Yun Industrial / ACME PCB Assembly, we specialize in both PCB manufacturing and assembly services, ensuring customers receive complete, end-to-end solutions with unmatched quality and precision.

What Is PCB Manufacturing?

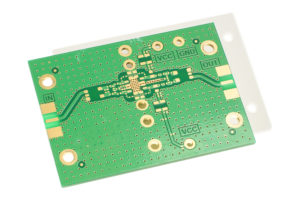

PCB manufacturing is the process of creating the physical printed circuit board from scratch. This involves several intricate steps, including:

-

Designing the board layout using CAD software

-

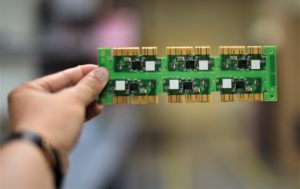

Creating a PCB prototype to test design accuracy

-

Layering copper and insulating materials to form conductive paths

-

Etching, drilling, and plating to create traces and vias

-

Applying solder masks and silkscreens for protection and labeling

Essentially, PCB manufacturing is about producing the bare board—the foundation that will later hold the electronic components. This stage requires high-precision machinery and engineering expertise to ensure the final board meets performance, safety, and durability standards.

What Is PCB Assembly?

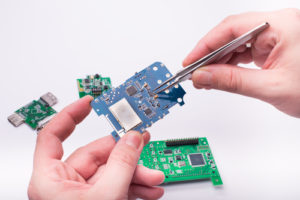

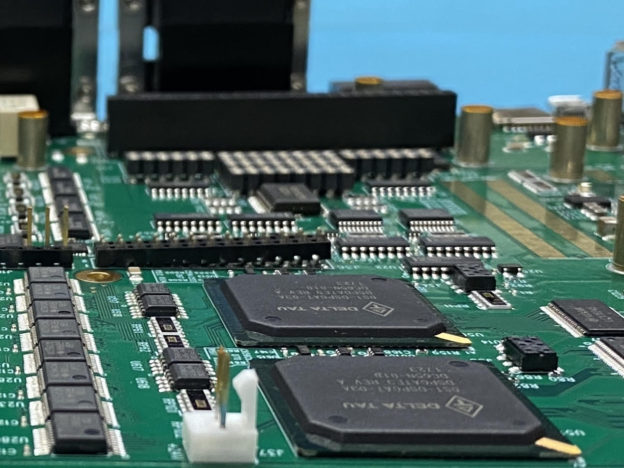

Once the bare board is manufactured, the next step is PCB assembly (PCBA). This is where the circuit board comes to life. The process involves soldering electronic components—such as resistors, capacitors, IC chips, and connectors—onto the PCB according to the design specifications.

PCB assembly can use Surface Mount Technology (SMT), Through-Hole Technology (THT), or a combination of both, depending on the application. This stage requires precise placement, temperature control, and soldering quality to ensure reliable electrical connections and functionality.

ACME PCB Assembly: Your One-Stop PCB Partner

At Yun Industrial ACME PCB Assembly, we provide both manufacturing and assembly services, eliminating the need to work with multiple vendors. As an ISO 9001:2015 certified Electronics Manufacturing Service (EMS) provider and IPC A-610 certified trainer, we uphold the highest industry standards for quality and reliability.

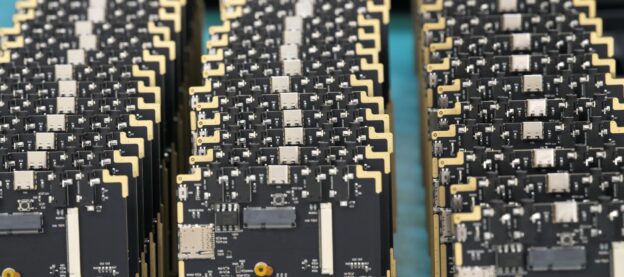

Every PCB we produce meets the strict guidelines of IPC 600, ensuring consistency, durability, and peak performance. Whether you need a prototype or large-scale production, ACME delivers the best value, competitive pricing, and on-time delivery—every time.

Contact us today to learn more about how ACME PCB Assembly can bring your next project from concept to completion.

Printed Circuit Boards (PCBs)

Printed Circuit Boards (PCBs) Following these PCB design best practices can lead to more efficient, reliable, and manufacturable

Following these PCB design best practices can lead to more efficient, reliable, and manufacturable

Find Your SMT and Through-Hole Vendor

Find Your SMT and Through-Hole Vendor

Flexible PCB Assembly for Every Project Size

Flexible PCB Assembly for Every Project Size