In today’s fast-paced electronics industry, there is a constant need for circuit board repair and rework. Whether due to design changes, component failure, or manufacturing defects, restoring and reusing existing printed circuit boards (PCBs) can save significant time and cost. At ACME PCB Assembly, we specialize in providing precise, reliable, and efficient rework and modification services to extend the life of your boards and ensure optimal performance.

Custom Rework Solutions for Every Project

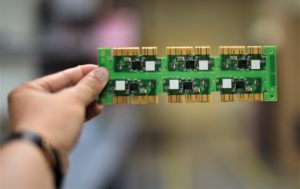

ACME PCB Assembly customizes each project to meet your specific requirements using a wide variety of leading-edge technologies. Our highly skilled technicians can complete standard projects quickly—often within one day of assembly—without compromising quality. We handle everything from small-scale component replacement to complex system-level repairs with exceptional accuracy and attention to detail.

Advanced PCB Repair Techniques

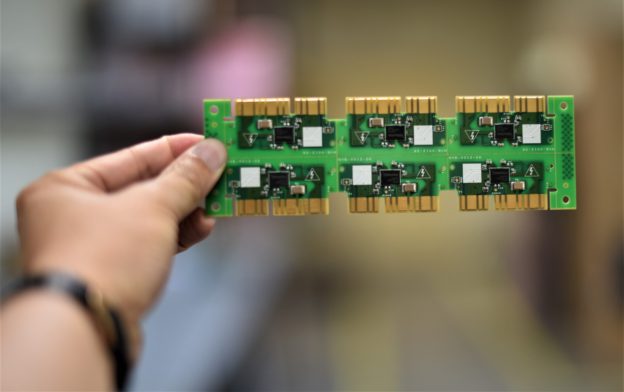

Our rework and repair services include refinishing, de-soldering, and re-soldering of all types of electronic printed circuit boards. Skilled manual techniques are combined with specialized equipment to replace defective or outdated components. This includes complex area array packages such as Ball Grid Array (BGA) devices, which require exceptional precision and temperature control.

We use hot air stations and rework tools to carefully heat solder joints, remove components, and reattach new ones—all while maintaining the integrity of surrounding parts. Our technicians are trained to handle miniature and delicate components, ensuring reliable reflow and alignment during replacement.

Save Money, Reduce Waste

Before you consign your damaged or outdated PCBs to the scrap bin, contact ACME PCB Assembly. Our expert rework and repair services can restore functionality, prevent waste, and save you money. In a market where every dollar counts, no company can afford to discard valuable boards that can be reworked and reused effectively.

Partner with ACME PCB Assembly for dependable repair services that bring your boards back to life. Call us today at 310.715.1898 to discuss your project and learn more about our rapid-turnaround rework solutions.

Board Assembly’s full turnkey services

Board Assembly’s full turnkey services

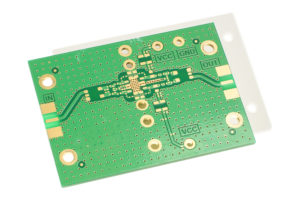

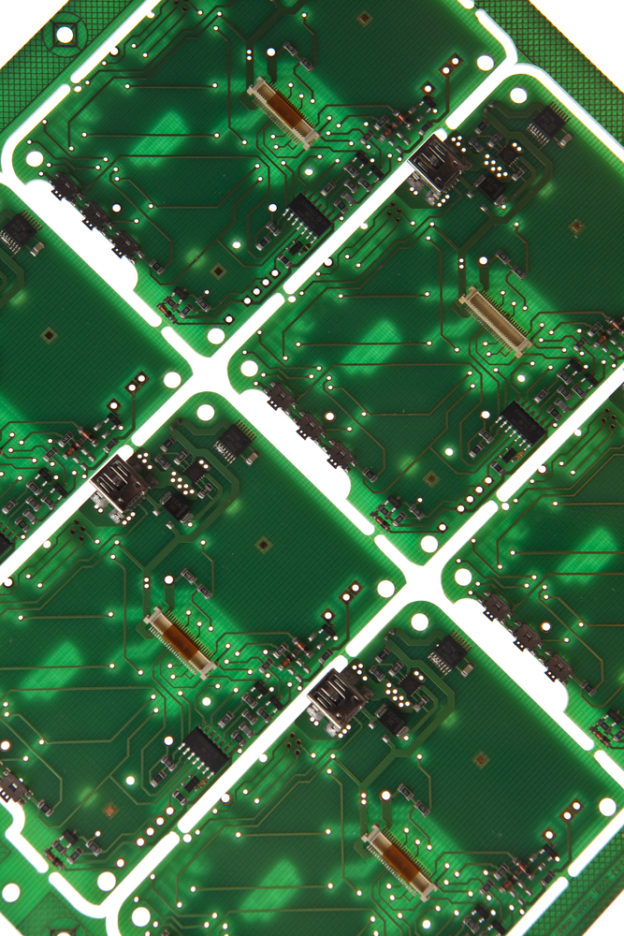

Printed Circuit Boards (PCBs)

Printed Circuit Boards (PCBs) Following these PCB design best practices can lead to more efficient, reliable, and manufacturable

Following these PCB design best practices can lead to more efficient, reliable, and manufacturable

When working on any tech-driven project, it’s crucial to focus on the longevity and performance of your components.

When working on any tech-driven project, it’s crucial to focus on the longevity and performance of your components.