Have you been sitting on an invention idea, waiting for the perfect moment to turn it into a real product? With 2026 right around the corner, now is the ideal time to take action. Whether you’re an entrepreneur, inventor, engineer, or startup founder, this can be the year you bring your idea out of your head and into the marketplace. And the best part? You don’t have to do it alone.

The journey from concept to finished product begins with one of the most crucial stages in development: New Product Introduction (NPI). NPI is where your idea becomes a structured plan, your design becomes tangible, and your vision starts taking shape. It covers everything from planning and engineering to prototyping and testing—steps that ultimately determine your product’s success.

The journey from concept to finished product begins with one of the most crucial stages in development: New Product Introduction (NPI). NPI is where your idea becomes a structured plan, your design becomes tangible, and your vision starts taking shape. It covers everything from planning and engineering to prototyping and testing—steps that ultimately determine your product’s success.

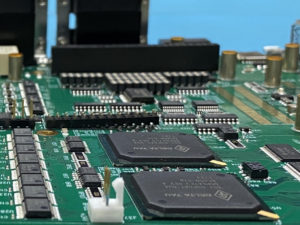

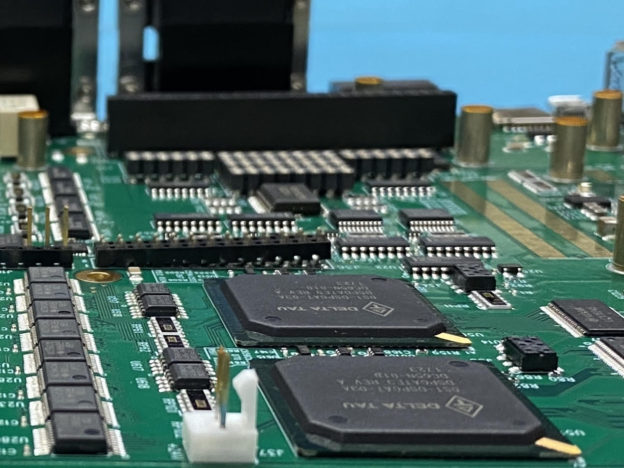

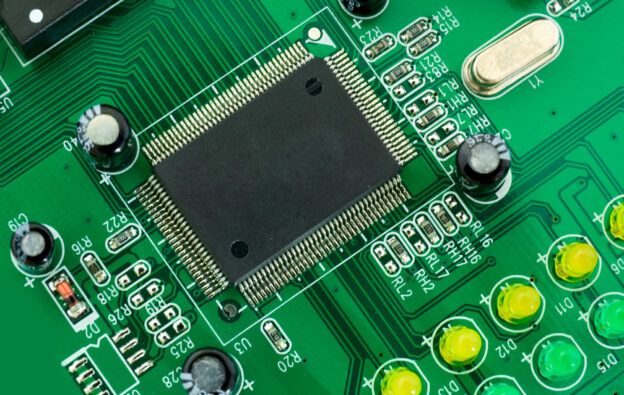

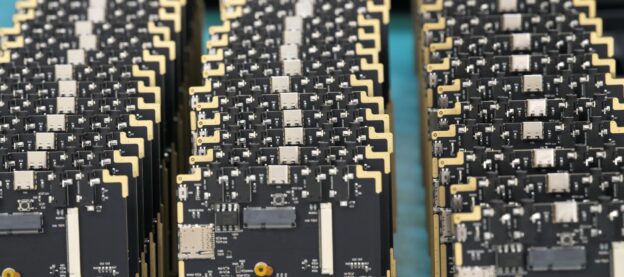

At Yun Industrial / ACME PCB Assembly, we specialize in making this stage efficient and achievable. With over 30+ years of experience in Electronic Manufacturing Services (EMS), our team has supported countless innovators by prototyping and assembling the printed circuit boards (PCBs) that make their inventions function.

From Concept to Prototype: Complete Support for Your PCB Needs

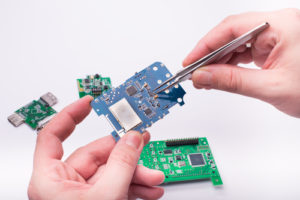

Worried that you don’t have a finalized PCB design or detailed schematics yet? That’s completely normal—and exactly where Yun Industrial’s engineering expertise becomes invaluable.

We guide you through every step of early development, including:

-

Initial planning and feasibility review

-

PCB design assistance and layout optimization

-

Component sourcing from trusted suppliers

-

Prototype fabrication

-

Testing, debugging, and rework when needed

If your invention includes mechanical parts, housings, molded components, or metal structures, we can connect you with additional vendors through our extensive network. This ensures you’re supported far beyond the PCB—giving you a complete path from idea to physical prototype.

With a working prototype in hand, you’ll be well-prepared to:

-

Present to investors

-

Conduct functional testing

-

Gather user feedback

-

Begin small-batch or large-scale production

Full-Service PCB Assembly for Every Stage of Development

Our capabilities go far beyond basic assembly. Yun Industrial / ACME PCB offers a comprehensive suite of services, including:

-

Prototype PCB Assembly

-

Turnkey PCB Assembly

-

SMT (Surface Mount Technology)

-

Thru-Hole Assembly

-

BGA Assembly & Rework

-

Lead-Free Assembly

-

Box Builds / Electromechanical Assemblies

We also support add-on manufacturing processes such as injection molding, metal work, and finishing services, making us a one-stop partner for your invention journey.

Make 2026 Your Year of Innovation

Make 2026 Your Year of Innovation

Too many great ideas never make it past the brainstorming stage. Let 2026 be the year you take the next step toward launching your invention. With the right engineering and manufacturing partner, your idea can become a working prototype—and eventually, a successful product.

Contact Yun Industrial / ACME PCB Assembly today to start prototyping the PCBs your innovation needs and make 2026 the year your product becomes reality.

To meet these demands, we invested in upgraded machinery, re-engineered our soldering and reflow processes, and strengthened temperature control systems to ensure long-term reliability. Just as important, our technicians underwent extensive retraining to understand the different properties, behaviors, and inspection details of lead-free solders. This comprehensive approach allows us to maintain exceptional quality while eliminating a major health and environmental hazard.

To meet these demands, we invested in upgraded machinery, re-engineered our soldering and reflow processes, and strengthened temperature control systems to ensure long-term reliability. Just as important, our technicians underwent extensive retraining to understand the different properties, behaviors, and inspection details of lead-free solders. This comprehensive approach allows us to maintain exceptional quality while eliminating a major health and environmental hazard.

Quality, Integrity, and Customer Partnership

Quality, Integrity, and Customer Partnership