Did You Know That We Can Also Rework Your Defective PCBs?

When you put in a large order for printed circuit boards from a PCB assembly service provider, you may find that a few circuit boards are defective in each bunch. Rather than write these circuit boards off as a loss (and lose your investment), you may be able to give them new life.

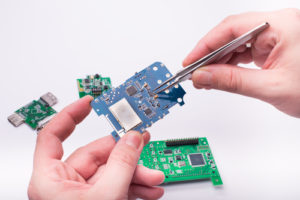

At ACME PCB Assembly, we may be able to re-work and repair some defective printed circuit boards. Often, this requires de-soldering and re-soldering components. This is manual work that must be performed by a trained technician. Fortunately, we have highly qualified staff members who can perform these repairs for you. This way, you don’t have to write off so many PCBs and can re-coup at least some of your costs.

PCB repair and rework services are an essential a process as manufacturing. Ensuring that any design flaw or damaged PCB component is repaired immediately will help maintain the PCB’s performance. In addition to these services, we conduct functional tests on your PCBs after the repair work is completed. This is performed to ensure that the device is running as per application and industry requirements.

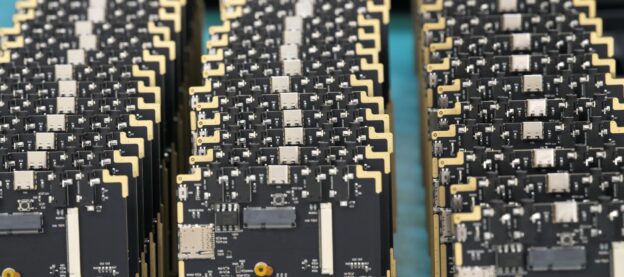

We closely match new incoming inquiries to board house equipment and capabilities, ensuring you receive only those inquiries that you are interested in Acme Circuit board assembly provide PCB fabrication service in the development and manufacturing of quality single, double sided and Multi-Layers printed circuit boards for the computer, medical, transportation, communication, aircraft, aerospace and related industries.

At ACME PCB Assembly, we take full responsibility for your printed circuit board order. This means we that we use only ACME PCB Assembly certified suppliers as our offshore partners.

Want to see what we can do? Contact us today to learn more about our PCB repair and modification services.

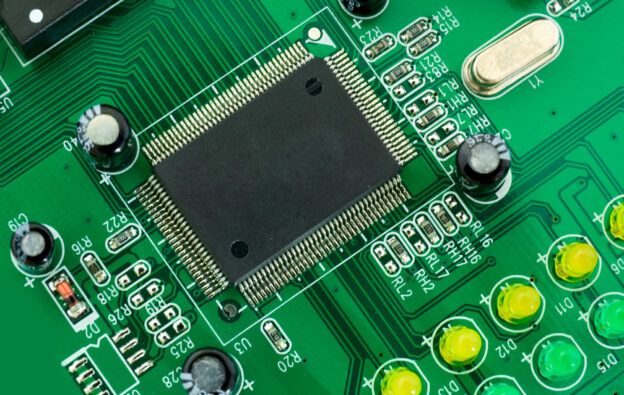

There are many theories why solder masks were originally green. One of the reasons was because when the solder mask was first produced, the base resin was a brownish yellow and the hardener was a muddy brown. When you combined these two components to form the solder mask, it turned green. Another theory was because green has been proven by many scientists that the color is the most visible and noticeable to the human eye. Colors are just different wavelengths and yellow and green are the wavelengths that are most easily noticeable under normal light. Green is the easiest to see, and easy on the eyes so they won’t tire the human out. This factor helps assemblers and quality control inspectors so maybe that is why green is the iconic color that the image of a

There are many theories why solder masks were originally green. One of the reasons was because when the solder mask was first produced, the base resin was a brownish yellow and the hardener was a muddy brown. When you combined these two components to form the solder mask, it turned green. Another theory was because green has been proven by many scientists that the color is the most visible and noticeable to the human eye. Colors are just different wavelengths and yellow and green are the wavelengths that are most easily noticeable under normal light. Green is the easiest to see, and easy on the eyes so they won’t tire the human out. This factor helps assemblers and quality control inspectors so maybe that is why green is the iconic color that the image of a

Quality, Integrity, and Customer Partnership

Quality, Integrity, and Customer Partnership