What the Heck Is Your PCB Vendor Talking About? – Common Terms for PCB Assembly

Every industry has its established lingo, which helps its members communicate more efficiently. If you are on the outside looking in, however, it can seem like they are speaking a foreign tongue. This becomes a problem when you need to work with vendors on ordering printed circuit boards for your device or your prototype. If you’ve gotten lost while trying to speak to your vendor (SMP, SME, SMD?), then you’ve come to the right place. Here is our no-nonsense guide on the most common terms in the printed circuit board industry:

Every industry has its established lingo, which helps its members communicate more efficiently. If you are on the outside looking in, however, it can seem like they are speaking a foreign tongue. This becomes a problem when you need to work with vendors on ordering printed circuit boards for your device or your prototype. If you’ve gotten lost while trying to speak to your vendor (SMP, SME, SMD?), then you’ve come to the right place. Here is our no-nonsense guide on the most common terms in the printed circuit board industry:

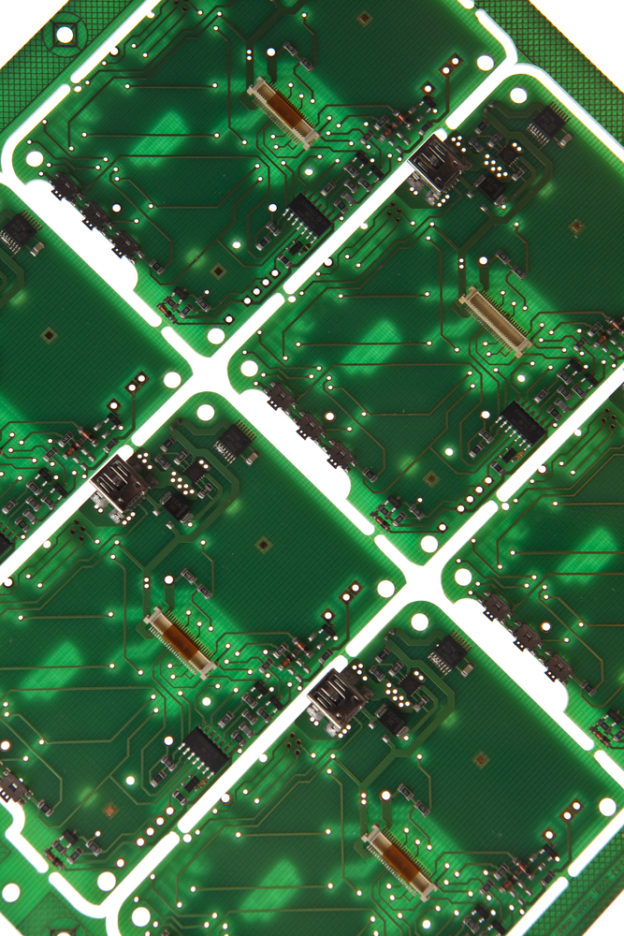

- PCB – Stands for Printed Circuit Board. Printed circuit boards are found in every single device that uses computing and data. PCBs act as the “highway” in transferring data between components within a device.

- THM – Stands for Through-Hole Mounting (also known as Thru-Hole Mounting). THM is an older assembly technology that mounts components on a PCB by drilling holes through the printed circuit board and placing component leads into the drilled holes. THM has largely been replaced by SMT assembly, though there are still some situations in which THM is preferred.

- SMT – Stands for Surface Mount Technology. SMT was first introduced in the 1960s and rose to prominence in the 1980s. Today, it is the dominant form of PCB assembly. SMT does not require drilling holes through a printed circuit board. Its components are smaller than THM and can be placed on both sides of the PCB. This allows for a denser allotment of components and a more powerful PCB.

- Substrate – The substrate is the actual board upon which wires and components are placed. It gives the PCB its structure and also insulates conductive parts. PCBs can be made from a variety of different substrates. All PCB substrates are non-conductive. Common substrate materials are: FR-4 (a fiberglass-epoxy laminate), Teflon, ceramics, specialized polymers

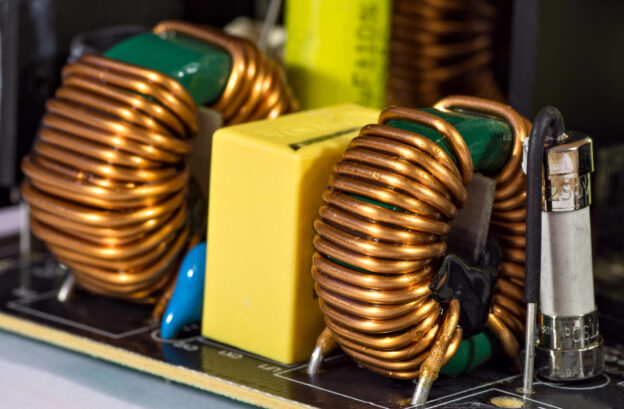

- Traces – Traces are the things that electrically connect the connectors to the components. The most common material for the traces is copper. The copper layer of a PCB goes on top of the substrate. In double-sided PCBs, copper traces are placed on both sides of the PCB.

- Soldermask – Have you ever wondered why almost all PCBs are green? This is the soldermask. This layer goes on top of the copper layer and functions to insulate the copper traces. It prevents the highly conductive copper traces from making contact with other metal components of the PCB.

While this is far from an exhaustive list of common terms used in the PCB industry, hopefully this guide will help you better understand and communicate with your printed circuit board manufacturer.

What Is a Contract Electronic Manufacturing Service Provider?

What Is a Contract Electronic Manufacturing Service Provider? Partner with a Trusted PCB Assembly Provider

Partner with a Trusted PCB Assembly Provider

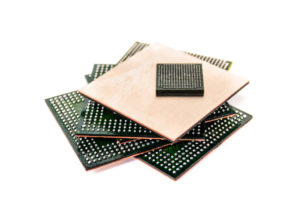

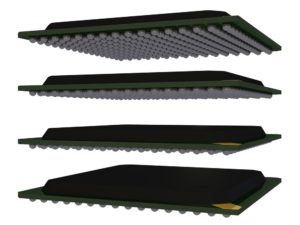

BGA (Ball Grid Array) is a surface-mount packaging technology that enhances electrical and thermal performance in PCBs. Unlike traditional dual in-line or quad flat packages, BGA uses an array of solder balls beneath the component rather than protruding pins. These solder balls establish electrical connections to the PCB, offering better heat dissipation, signal integrity, and mechanical stability.

BGA (Ball Grid Array) is a surface-mount packaging technology that enhances electrical and thermal performance in PCBs. Unlike traditional dual in-line or quad flat packages, BGA uses an array of solder balls beneath the component rather than protruding pins. These solder balls establish electrical connections to the PCB, offering better heat dissipation, signal integrity, and mechanical stability. While BGA Assembly offers numerous benefits, ensuring flawless soldering and defect-free connections is crucial. Advanced techniques like X-ray inspection and reflow soldering help detect hidden defects and guarantee the highest level of precision.

While BGA Assembly offers numerous benefits, ensuring flawless soldering and defect-free connections is crucial. Advanced techniques like X-ray inspection and reflow soldering help detect hidden defects and guarantee the highest level of precision.