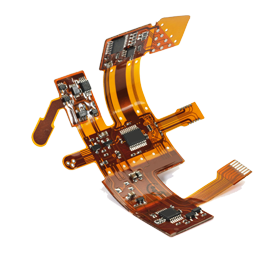

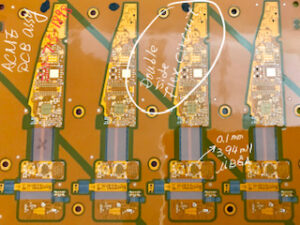

The design rules for flex turnkey PCB assembly is very similar to the design rules for traditional PCBs. Traditional PCBs and flex flex turnkey PCB assembly share some similarities in the manufacturing process as well. To start, the flexible circuit board material (typically copper clad Polyimide) is chosen, drilled, plated, photo-imaged, and imprinted just like the conservative PCB process. Next, both PCBs and flex turnkey PCB assemblies involve the panels being baked to remove any moisture from the wet processes. This next step is where the original PCB and flex turnkey PCB assembly start to differ. Flex turnkey PCB assemblies go to the cover lay station instead of going to the fuse mask station, as would occur with traditional PCBs.

A flex circuit board cover lay, also known as a cover film, is a lamination process used to summarize and protect any peripheral circuitry of the flex circuit. The cover lay serves the similar function as the solder mask does for conventional PCBs with the dissimilarity being the added component of flexibility. Naturally, the thickness of the cover lay is prepared of 1 mil thick Polyimide with a 1 mil thick, attach adhesive, but other thicknesses are accessible to meet precise design necessities. The Polyimide and adhesive cover lay is laminated using force and heat.

The heat allows for simple flow of the adhesive which is needed because it must fill-in any and all gaps among the traces and pads to stop the trapping of air between layers. To a flex turnkey PCB assembly designer this means the cover lay openings for a characteristic 1 oz. The copper plan must be out-sized by 10 mils, which is appreciably bigger than the typical huge of 2-3 mils used on conventional PCB solder masks.

The heat allows for simple flow of the adhesive which is needed because it must fill-in any and all gaps among the traces and pads to stop the trapping of air between layers. To a flex turnkey PCB assembly designer this means the cover lay openings for a characteristic 1 oz. The copper plan must be out-sized by 10 mils, which is appreciably bigger than the typical huge of 2-3 mils used on conventional PCB solder masks.

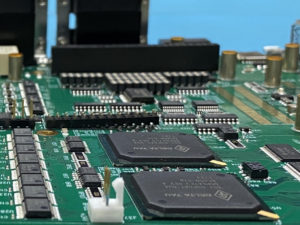

ACME PCB Assembly manufactures flexible turnkey PCB assembly. We can take your flexible circuit application from concept to reality with our complete design capabilities. Our talented team is equipped to work in multiple data formats. We have in-house surface-mount technology (SMT) capabilities and specialize in turnkey assembly applications.

ACME PCB Assembly will work with you for all of your flexible circuit board needs. We are committed to not only customer satisfaction, but exceeding our customer’s expectations. Our adherence to quality standards is a part of what makes our boards superior to other suppliers.

We provide a complete suite of PCB Assembly Services, including rework and modification, BGA, SMT, Turnkey, Thru-Hole, Lead Free, and Prototype assembly, plus an extensive line of add-on services, such as Injection Molding and Metal Work & Finishing.

Call us today with any questions 1- 310-715-1898 (Sales Extension 210) (Purchasing Extension 160)

Is Flexible PCB Assembly Right for You?

Is Flexible PCB Assembly Right for You?

Find Your SMT and Through-Hole Vendor

Find Your SMT and Through-Hole Vendor

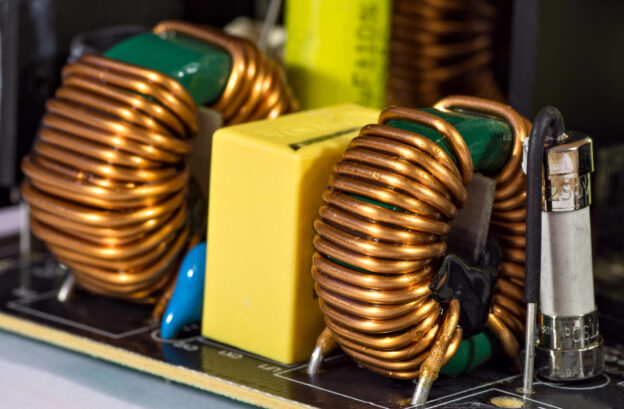

With everyone’s increasing concerns on the over usage of hazardous materials in the electronic and electrical products and their environmental impact, there have been several stricter regulations being imposed by the leading governmental organizations across the world. The RoHS compliance is one of those important regulations that is currently being imposed on the utilization of hazardous materials in the electronics and electrical products. Are you interested in knowing how this compliance works or what the benefits are?

With everyone’s increasing concerns on the over usage of hazardous materials in the electronic and electrical products and their environmental impact, there have been several stricter regulations being imposed by the leading governmental organizations across the world. The RoHS compliance is one of those important regulations that is currently being imposed on the utilization of hazardous materials in the electronics and electrical products. Are you interested in knowing how this compliance works or what the benefits are?

What Is a Contract Electronic Manufacturing Service Provider?

What Is a Contract Electronic Manufacturing Service Provider? Industries That Benefit from PCB Assembly Services

Industries That Benefit from PCB Assembly Services Partner with a Trusted PCB Assembly Provider

Partner with a Trusted PCB Assembly Provider