How to Create an Electronic Prototype

Do you have a big idea for a new electronic product? We all know that ideas are a dime a dozen, so if you really want to get your idea off the ground, eventually you’ll need to create a prototype. A prototype, simply put, is a physical manifestation of a product. There are many important reasons to create a prototype. In this article, we’ll also review some quick tips about how to turn your idea into a prototype.

Why Prototype?

Creating a prototype is an essential step in your journey to bring your product to market. One of the biggest reasons to create a prototype is to simply work out all the bugs and kinks. Designing the prototype will help you determine if you’ve got the size right, if it can really work as you’ve imagined, and what the best materials are.

A prototype is also practically a requirement if you’re looking for seed money. No investor is going to write you a check if you aren’t at least serious enough to show them an early model of your product.

How to Create a Prototype

A prototype starts with a drawing. You can take an actual pen to paper for this step, but eventually it’s a good idea to either create or commission a CAD drawing (computer-aided design), which will provide greater detail and accuracy.

Next, you may want to try and build a preliminary prototype of y our product just to test out the dimensions and see what it will look like. This will not be a working prototype. If you are handy, you may be able to fashion it yourself using foam, moldable plastic, metal, wood, or parts from other products.

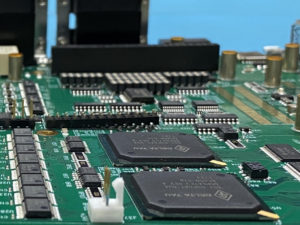

Eventually, though, you’ll want to create a working prototype. This will be important to showcase to investors. Since you are creating an electronic product, it is likely that you’ll want to work with professional prototype developers. These are manufacturers who specialize in developing prototypes. They are experienced in helping entrepreneurs and inventors just like you figure out how to actually create the prototype. For example, they can help you determine the right materials and figure out how the actual product will work.

What Is Conformal Coating?

What Is Conformal Coating?

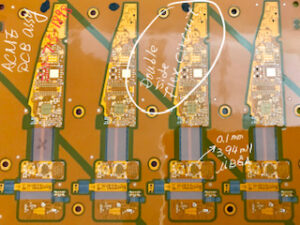

Is Flexible PCB Assembly Right for You?

Is Flexible PCB Assembly Right for You?

Find Your SMT and Through-Hole Vendor

Find Your SMT and Through-Hole Vendor

With everyone’s increasing concerns on the over usage of hazardous materials in the electronic and electrical products and their environmental impact, there have been several stricter regulations being imposed by the leading governmental organizations across the world. The RoHS compliance is one of those important regulations that is currently being imposed on the utilization of hazardous materials in the electronics and electrical products. Are you interested in knowing how this compliance works or what the benefits are?

With everyone’s increasing concerns on the over usage of hazardous materials in the electronic and electrical products and their environmental impact, there have been several stricter regulations being imposed by the leading governmental organizations across the world. The RoHS compliance is one of those important regulations that is currently being imposed on the utilization of hazardous materials in the electronics and electrical products. Are you interested in knowing how this compliance works or what the benefits are?