Why apply conformal coating?

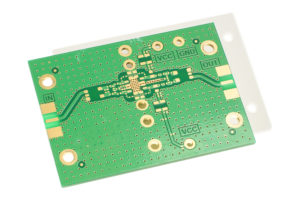

Printed Circuit Boards (PCB) is the core of everyday life as most electrical devices can not function without one. From everyday life to military and medical situations, a PCB must be able to withstand the wear and tear of time and other elements. Conformal coating is designed to protect Printed Circuit Board (PCB), and related equipment from their environment. Typically applied at 0.001 inches to 0.003 inches on the PCB. It is a protective nonconductive dielectric layer that is applied to the assembled printed circuit boards to protect the electronic product from damage due to contamination, salt spray, moisture, fungus, dust, and corrosion caused by the harsh or extreme environment.

ACME PCB Assembly happens to offer three different kinds of conformal coating for our valuable customers. The acrylic conformal coating is a low viscosity coating that is cured through drying and isn’t too resistant to chemicals but hardens quickly. The Urethane conformal coating is also a low viscosity coating, however, is cured through crosslinking with strong resistances to chemicals. Silicone conformal coating is a very viscous coating that is applied through swirl technology with high chemical resistances.

ACME PCB Assembly happens to offer three different kinds of conformal coating for our valuable customers. The acrylic conformal coating is a low viscosity coating that is cured through drying and isn’t too resistant to chemicals but hardens quickly. The Urethane conformal coating is also a low viscosity coating, however, is cured through crosslinking with strong resistances to chemicals. Silicone conformal coating is a very viscous coating that is applied through swirl technology with high chemical resistances.

Below is a graph that shows the characteristics of the conformal coatings ACME PCB Assembly provides.

| Acrylic conformal coating | Urethane conformal coating | Silicone conformal coating | |

| Viscosity | Low | Low | High |

| Typical applicator technology | Film coating | Film coating / Swirl | Swirl |

| Curing | Drying | Crosslinking | Crosslinking |

| Volatile Organic Compound (VOC) | Yes | Yes | No |

| Chemical resistance | Low | High | High |

| Thermal span | Low | Low | High |

| Glass Transition Temp | Low | Low | N/A |

| Repairable | Solvents | Solvents & Mechanical.

May result in stratified coating after repair.

|

Solvents & Mechanical.

May result in stratified coating after repair.

|

Call 310-715-1898 or email steve@acme-pcbassembly.com for a free quote.

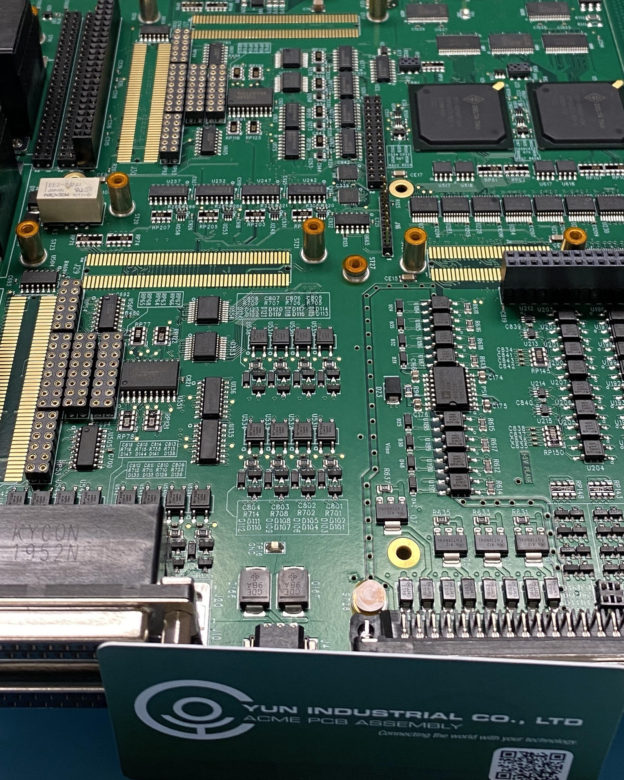

ACME PCB Assembly

ACME PCB Assembly

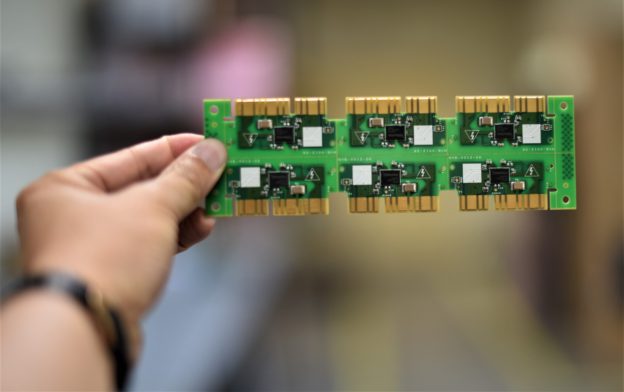

One of the most important steps in bringing any new electronic device to market is completing the prototype phase. A prototype doesn’t just prove that your idea can work; it becomes the foundation for improving your design, testing functionality, pitching investors, and preparing for manufacturing. At ACME PCB Assembly, we specialize in helping inventors, entrepreneurs, and start-ups build the printed circuit boards (PCBs) their products depend on.

One of the most important steps in bringing any new electronic device to market is completing the prototype phase. A prototype doesn’t just prove that your idea can work; it becomes the foundation for improving your design, testing functionality, pitching investors, and preparing for manufacturing. At ACME PCB Assembly, we specialize in helping inventors, entrepreneurs, and start-ups build the printed circuit boards (PCBs) their products depend on.