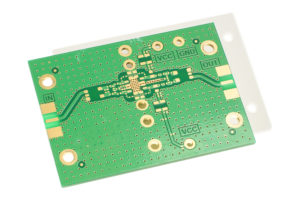

Do you have a new PCB idea that you’re excited to bring to life? Once your design is finalized and ready for production, it’s tempting to jump straight into a large manufacturing order—especially if you believe the product will sell quickly. But before committing to thousands of units, there’s a far more important question to ask: Will the PCB actually work the way you expect once produced in large quantities?

This is exactly why PCB Assembly strongly recommends performing a trial run before entering mass production. A trial run ensures that your design functions properly, that the build process is stable, and that potential problems are identified early—before they become costly and time-consuming.

What Is a Trial Run in PCB Manufacturing?

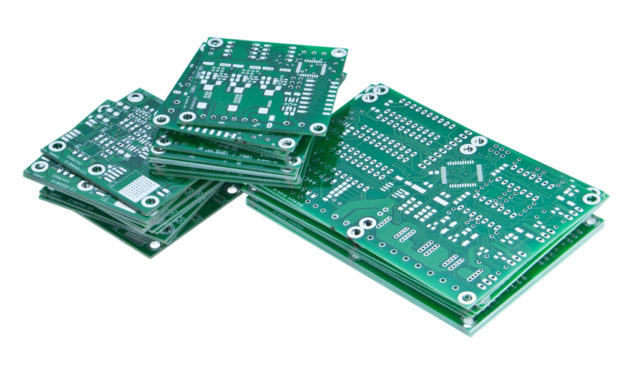

A trial run, also known as a pilot run or pre-production build, is essentially a mini mass-production cycle. Instead of producing all 6,000 units immediately, the trial run starts with a much smaller batch, typically around 200 units.

If that initial batch performs well, the order is scaled up to 1,000 units, allowing the engineering and manufacturing teams to:

-

Verify component integrity

-

Validate soldering processes

-

Confirm assembly consistency

-

Identify design or manufacturing flaws

-

Test the product under realistic conditions

Only after the 200- and 1,000-unit runs are successful do we move forward with the full order—such as the complete 6,000-piece production you originally planned.

This method reduces financial risk and ensures that your PCB performs flawlessly before mass production begins.

Why You Should Never Skip the Trial Run

Unfortunately, many companies—especially those importing parts or outsourcing overseas—skip the trial run because they are pressed for time or eager to deliver products to their customers. However, bypassing this stage can result in:

Unfortunately, many companies—especially those importing parts or outsourcing overseas—skip the trial run because they are pressed for time or eager to deliver products to their customers. However, bypassing this stage can result in:

-

Costly redesigns

-

Wasted materials

-

Delayed shipments

-

Failed PCBs

-

Customer dissatisfaction

-

Damage to your brand

A trial run acts as a quality gate, ensuring that your idea translates into a stable, functional, and manufacturable product. It provides the opportunity to confirm that the production line is operating correctly, that the PCB layout translates properly, and that the assembly team can reproduce your design consistently.

Trial Runs Protect Your Investment

Producing thousands of PCBs without first validating the process is a major financial risk. A trial run prevents:

-

Large-scale defects

-

Incorrect component placement

-

Soldering issues

-

Tolerance mismatches

-

Unforeseen board failures

Catching these issues early can save you tens of thousands of dollars and prevent product launch delays.

Start Smart—Test Before You Scale

Whether you’re launching your first PCB design or preparing to scale an existing one, a trial run is one of the most important early steps in the manufacturing process. PCB Assembly is here to guide you through each phase—from prototype to pilot run to full production—ensuring your product works the way it should.

Before you invest in mass production, invest in certainty. Contact us today to schedule your trial run and protect your next big product.

PCB production is traditionally resource-intensive. It requires large amounts of raw materials, water, energy, and chemical processing. Without proactive sustainability efforts, these processes can contribute to carbon emissions, hazardous waste, and long-term environmental damage. At the same time, many OEMs and end users now demand greener supply chains. Regulatory pressure is increasing, and corporate responsibility expectations are higher than ever. Sustainable PCB manufacturing is now essential to long-term business success and global environmental stewardship.

PCB production is traditionally resource-intensive. It requires large amounts of raw materials, water, energy, and chemical processing. Without proactive sustainability efforts, these processes can contribute to carbon emissions, hazardous waste, and long-term environmental damage. At the same time, many OEMs and end users now demand greener supply chains. Regulatory pressure is increasing, and corporate responsibility expectations are higher than ever. Sustainable PCB manufacturing is now essential to long-term business success and global environmental stewardship. By selecting a manufacturer committed to sustainable production, businesses take an active role in protecting the environment without sacrificing performance or reliability.

By selecting a manufacturer committed to sustainable production, businesses take an active role in protecting the environment without sacrificing performance or reliability.

1. Understand Your Application Requirements

1. Understand Your Application Requirements

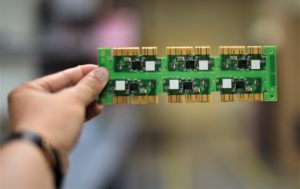

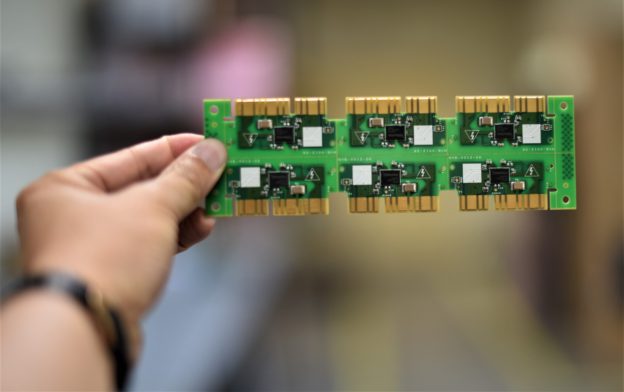

One of the most important steps in bringing any new electronic device to market is completing the prototype phase. A prototype doesn’t just prove that your idea can work; it becomes the foundation for improving your design, testing functionality, pitching investors, and preparing for manufacturing. At ACME PCB Assembly, we specialize in helping inventors, entrepreneurs, and start-ups build the printed circuit boards (PCBs) their products depend on.

One of the most important steps in bringing any new electronic device to market is completing the prototype phase. A prototype doesn’t just prove that your idea can work; it becomes the foundation for improving your design, testing functionality, pitching investors, and preparing for manufacturing. At ACME PCB Assembly, we specialize in helping inventors, entrepreneurs, and start-ups build the printed circuit boards (PCBs) their products depend on.