-

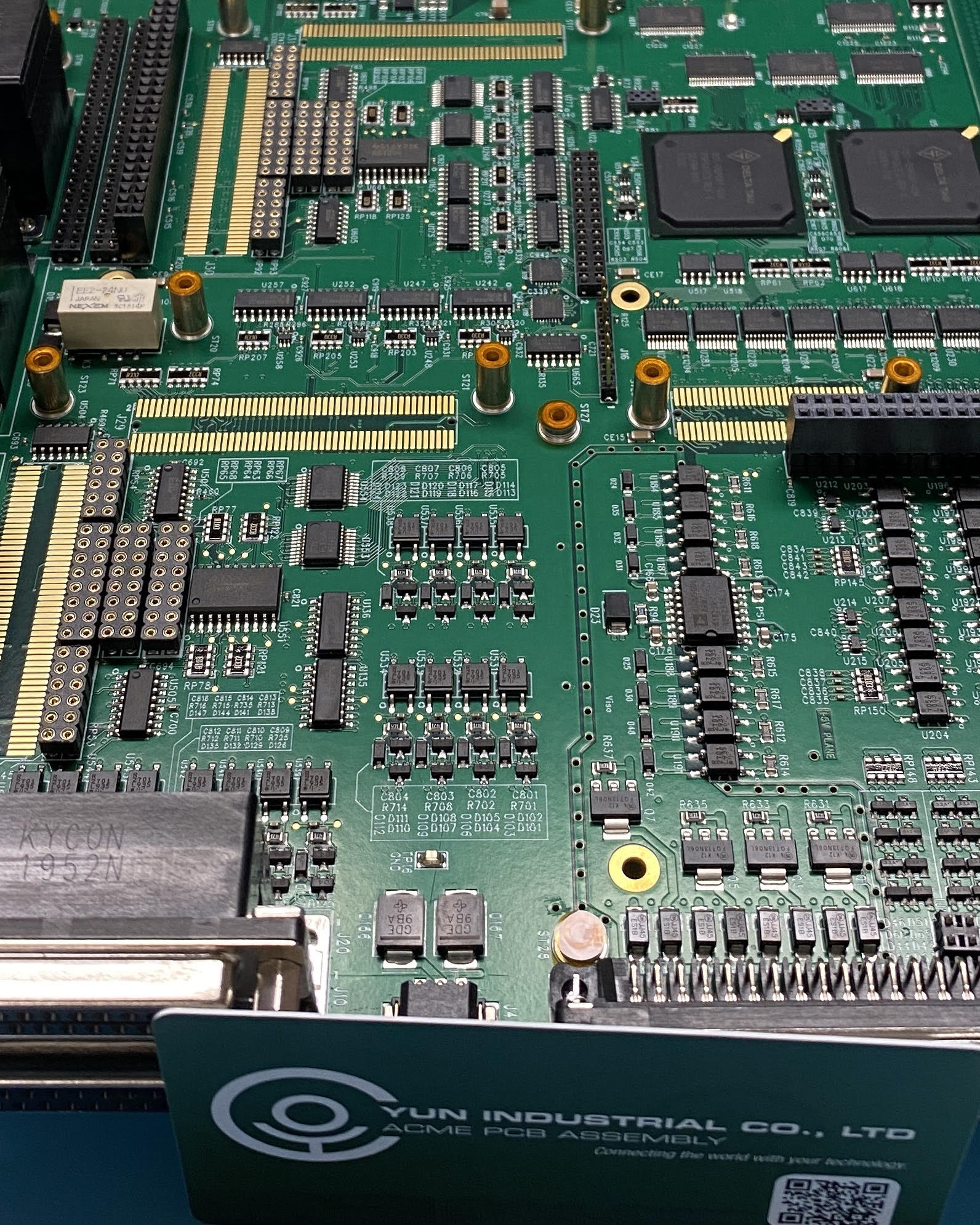

Providing Electronics Manufacturing Services (EMS) Since 1993 The electronic manufacturing services (EMS) industry took off after the late 1970’s. Before this, most electronics manufacturing that was done in large quantity production runs was handled by in-house assembly only. Now, the electronic manufacturing services (EMS) provider offers more flexibility and easier resources to deal with issues for smaller companies who doing limited runs. An electronic manufacturing services (EMS) provider is able to specialize in large manufacturing,

-

Acrylic resins (AR) are single component materials. To specify, they are preformed acrylic polymers that are dissolved in a solvent to be applied to surfaces. One main benefit of using an Acrylic conformal coating service on your electronics is it provides an excellent barrier to moisture/humidity and have good fungus resistance. They also have minimal chemical resistance which makes it ideal for reworking and removability. Acrylic Conformal Coating can be easily applied with a brush,

-

In today’s fast-paced electronics industry, businesses rely on contract electronic manufacturing service providers to streamline their production processes. Whether you need prototypes or full-scale production, partnering with a reliable manufacturer ensures high-quality PCB assembly and efficient turnaround times. What Is a Contract Electronic Manufacturing Service Provider? A contract electronic manufacturing service (CEMS) provider specializes in producing electronic components, circuit boards, and complete assemblies for various industries. These manufacturers handle everything from PCB fabrication and PCB

-

In the world of modern electronics, achieving optimal performance, reliability, and miniaturization is essential. Ball Grid Array (BGA) Assembly has emerged as a key technology in printed circuit board (PCB) manufacturing, enabling high-speed performance and superior durability. As industries continue to push for more compact and efficient devices, BGA Assembly plays a critical role in ensuring electronic components meet rigorous demands. What Is BGA Assembly? BGA (Ball Grid Array) is a surface-mount packaging technology that

-

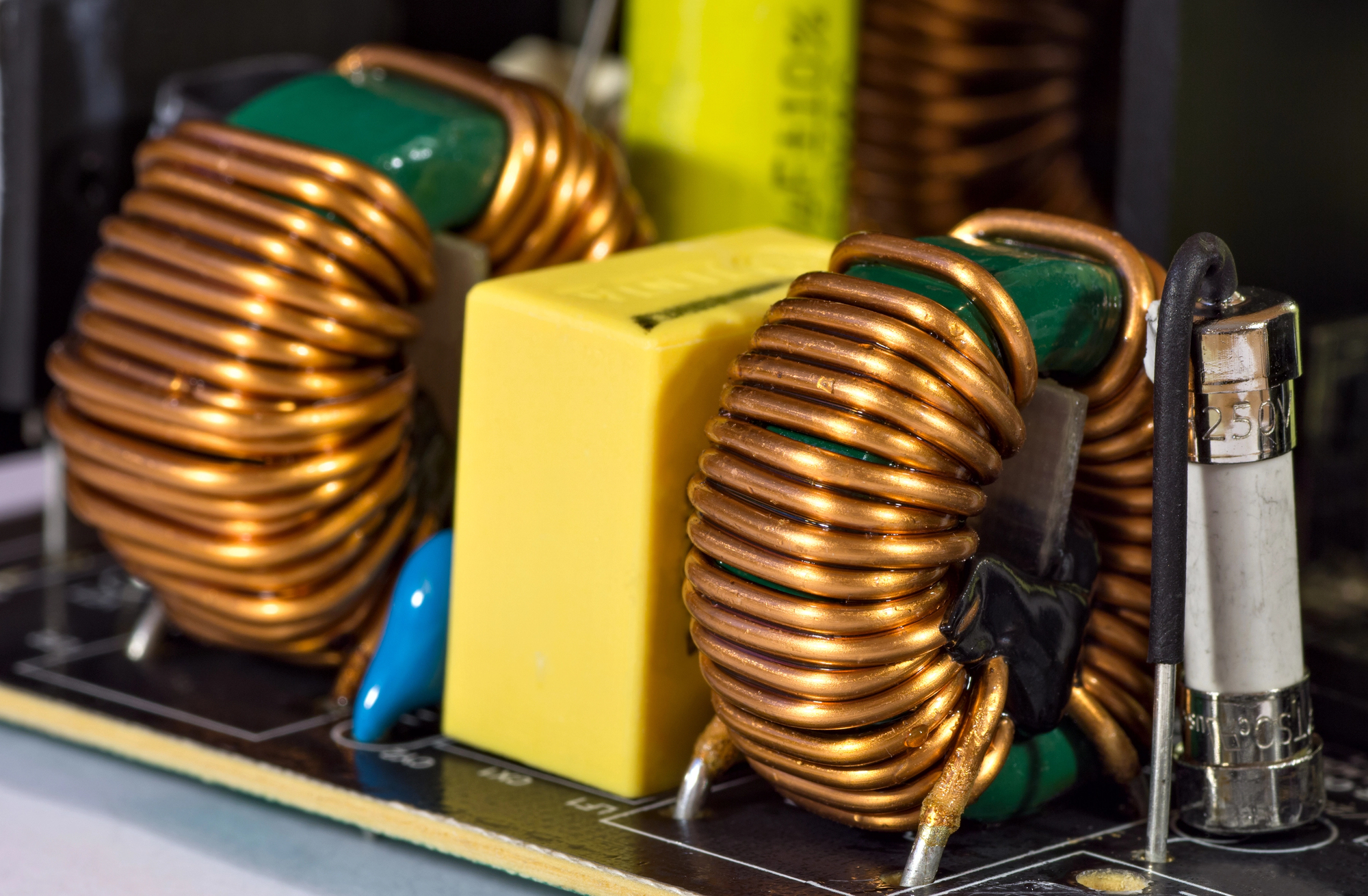

Why apply conformal coating? Printed Circuit Boards (PCB) is the core of everyday life as most electrical devices can not function without one. From everyday life to military and medical situations, a PCB must be able to withstand the wear and tear of time and other elements. Conformal coating is designed to protect Printed Circuit Board (PCB), and related equipment from their environment. Typically applied at 0.001 inches to 0.003 inches on the PCB. It is