Why Consider Using Through Hole Printed Circuit Boards?

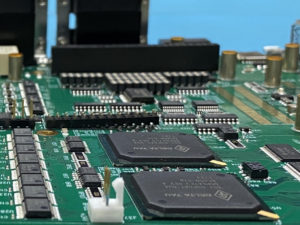

In the printed circuit board business, there are two primary ways to mount components onto the circuit board: through-hole mounting and surface mounting. Through-hole mounting is the older technology and requires the circuit board manufacturer to drill holes through the PCB and place leads into the holes. More recently, surface mounted technology has taken over the field.

In the printed circuit board business, there are two primary ways to mount components onto the circuit board: through-hole mounting and surface mounting. Through-hole mounting is the older technology and requires the circuit board manufacturer to drill holes through the PCB and place leads into the holes. More recently, surface mounted technology has taken over the field.

Through-Hole Components

Through-hole components come in one of two types of leads, radial and axial. Axial through-hole components run along the axis of symmetry of the component while radial components protrude in parallel from the same surface on a board.

Components of Surface Mount Technology

When you look at any modern PCB design, you will see SMT technology in most instances. Surface mount technology (SMT) is the most commonly used technology today. These types of boards and components have very small or no leads at all as their primary purpose is to be soldered directly on the surface of a PCB during the design process. This method allows for components to be much smaller, allowing for greater density and better overall performance on a smaller circuit board.

With surface mounting offering so many benefits, why even consider through hole flex printed circuit boards?

The reason is that through hole mounting offers stronger mechanical bonds. This makes through hole flex printed circuit boards the better option for devices that are designed to undergo major stresses, like sudden accelerations, collisions, or extreme temperatures. This makes them worth considering for military, automotive, and extreme sports applications.

Yun Industrial Acme PCB Assembly is capable of two types of printed circuit board assembly services. They are full and partial turn-key services. Full turn-key covers all aspects of PCB fabrication and assembly, including manufacture of PCBs, parts procurement, quality inspections, and final PCB assembly.

Find Your SMT and Through-Hole Vendor

Find Your SMT and Through-Hole Vendor