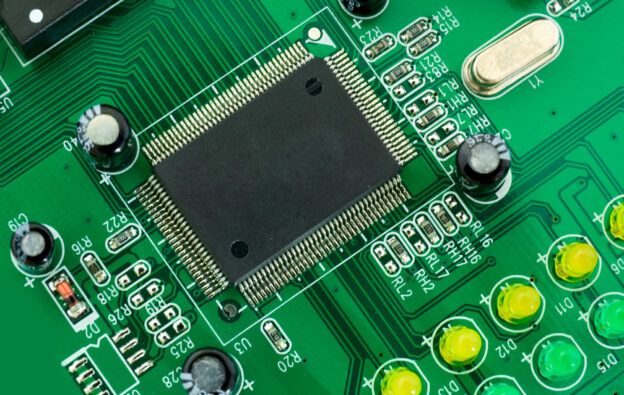

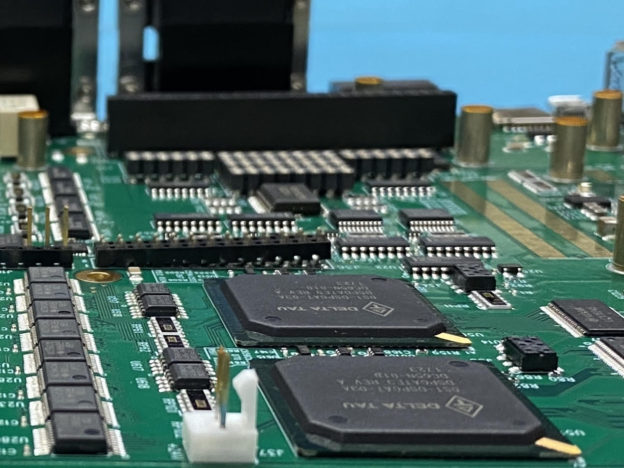

Printed Circuit Boards (PCBs) are the backbone of modern electronics, found in everything from smartphones to medical devices.

Printed Circuit Boards (PCBs) are the backbone of modern electronics, found in everything from smartphones to medical devices.

At Board Assembly, we pride ourselves on our comprehensive PCB manufacturing process, which ensures top-quality products for a wide range of industries. In this blog, we’ll walk you through the PCB manufacturing process, from initial design to the final product.

1. Design and Layout

The PCB manufacturing journey begins with the design phase. Engineers use specialized software to create a detailed layout of the circuit. This design includes the placement of components, electrical connections, and layer configuration. Ensuring a robust design is crucial as it sets the foundation for the entire manufacturing process.

Key Steps in Design:

- Schematic Capture: Creating a schematic diagram to represent the circuit.

- Layout Design: Using CAD software to design the PCB layout.

- Design Rule Check (DRC): Ensuring the design meets manufacturing specifications.

For more details on our design capabilities, visit our PCB Design Services.

Once the design is finalized, a prototype is created. Prototyping is essential to test the design for functionality and performance before mass production. At Board Assembly, we utilize advanced prototyping techniques to ensure quick and accurate results.

- Material Selection: Choosing the appropriate materials for the PCB.

- Initial Fabrication: Creating a small batch of PCBs for testing.

- Testing and Validation: Conducting thorough tests to verify the design.

Explore our Prototyping Services to learn how we can assist in bringing your designs to life.

3. Material Procurement

The next phase involves procuring the necessary materials. This includes the substrate, copper cladding, and various components like resistors, capacitors, and ICs. Quality materials are vital for the reliability and longevity of the PCB.

Considerations in Material Procurement:

- Component Quality: Sourcing high-quality components from reputable suppliers.

- Supply Chain Management: Ensuring timely delivery of materials.

- Cost Management: Balancing quality with cost-effectiveness.

Find out more about our Material Procurement Process.

4. PCB Fabrication

PCB fabrication is where the actual manufacturing begins. This process involves several steps to transform the design into a physical PCB.

Fabrication Steps:

- Etching: Removing excess copper to create the circuit pattern.

- Lamination: Stacking and bonding multiple layers of the PCB.

- Drilling: Creating holes for component leads and vias.

- Plating: Adding a layer of conductive material to the drilled holes.

Learn about our PCB Fabrication Techniques for a detailed overview.

5. Assembly

After fabrication, the PCB moves to the assembly phase. This is where components are placed and soldered onto the board.

Assembly Methods:

Discover our PCB Assembly Services to see how we ensure precision and reliability.

6. Testing and Quality Control

Quality control is a critical step to ensure the final product meets all specifications and performance criteria. At Board Assembly, we perform rigorous testing and inspection.

Testing Techniques:

- Automated Optical Inspection (AOI): Using cameras to inspect the PCB.

- X-Ray Inspection: Checking for hidden defects.

- Functional Testing: Ensuring the PCB performs as intended.

Visit our Quality Control Process page to learn more about our commitment to excellence.

7. Final Product and Delivery

Once the PCBs pass all tests, they are ready for delivery. We ensure that each board is packaged securely and delivered on time to our clients.

Delivery Considerations:

Learn more about our Delivery and Support Services.

The PCB manufacturing process is complex and requires meticulous attention to detail at every stage. At Board Assembly, we are dedicated to delivering high-quality PCBs that meet your specific requirements. Whether you need design assistance, prototyping, or full-scale production, we have the expertise and technology to bring your projects to life.

For more information on our services, contact us and let us help you with your next PCB project.

Printed Circuit Boards (PCBs) are the backbone of modern electronics, found in everything from smartphones to medical devices.

Printed Circuit Boards (PCBs) are the backbone of modern electronics, found in everything from smartphones to medical devices.