-

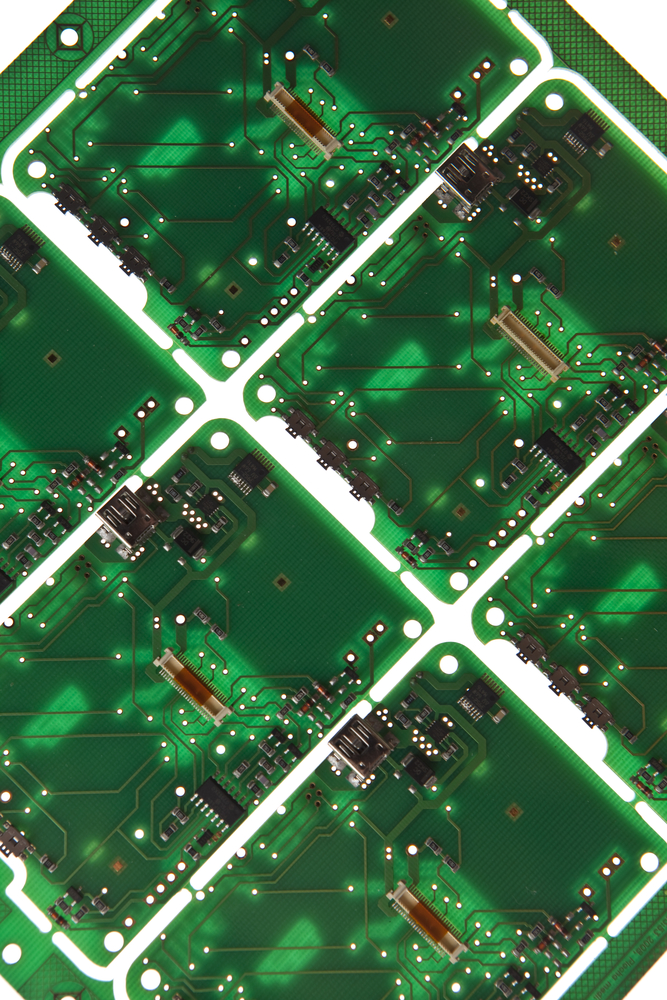

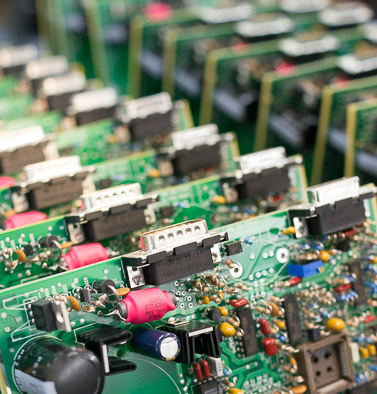

In today’s fast-paced technology landscape, using high-quality PCBs in your projects is essential for success. Printed circuit boards form the backbone of countless devices, from smartphones to industrial machines, and their performance can make or break your innovation. Ensuring that the printed circuit boards you select meet rigorous standards and are produced under stringent quality control measures is key to delivering reliable, durable, and efficient products. When working on any tech-driven project, it’s crucial to

-

When it comes to printed circuit board (PCB) manufacturing, the terms “full turnkey” and “turn-key assembly” are often synonymous with efficiency, quality, and convenience. At Board Assembly, we offer comprehensive solutions that cater to every aspect of PCB production. Our full turnkey services are designed to streamline the entire process, from initial design and prototyping to final production and testing, ensuring that every product meets the highest standards of quality and reliability. What is

-

We are proud to announce the addition of the Omron 3D AOI S1080 system to our production line, a major investment dedicated to maintaining and enhancing the highest standards of SMT assembly quality. As electronic products continue to evolve toward miniaturization, higher complexity, and greater reliability requirements, the importance of consistent inspection and process control has never been more critical. The Omron S1080 represents the latest generation of 3D Automated Optical Inspection (AOI) technology. With

-

Cable Assemblies include one or more wires that run together in a single sleeve with a connector or plug on each end. Cable assemblies could be groups of wires or cables bundled together. They are wrapped in a thermoplastic or vinyl sleeve, cable assemblies are ideal for directing groups of wires and cables around obstacles. Cable assemblies are designed to perform specific functions that is determined by the plugs, terminals, and connectors that are found on each end.

-

Why Consider Using Through Hole Printed Circuit Boards? In the printed circuit board business, there are two primary ways to mount components onto the circuit board: through-hole mounting and surface mounting. Through-hole mounting is the older technology and requires the circuit board manufacturer to drill holes through the PCB and place leads into the holes. More recently, surface mounted technology has taken over the field. Through-Hole Components Through-hole components come in one of two types