-

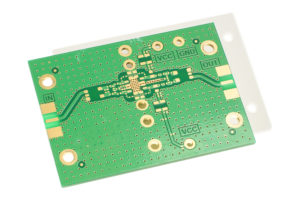

The world of printed circuit board (PCB) technology is evolving rapidly. As design demands grow denser, smarter, and more compact, three trends are defining the next generation of electronics: High-Density Interconnect (HDI), Flexible & Rigid-Flex PCBs, and Embedded Components. At Board Assembly, we’re keeping a close eye on these advances to ensure our clients stay ahead of the curve. 1. HDI: Packing More into Less HDI technology enables PCBs with tighter trace spacing, smaller vias,

-

In today’s fast-paced electronics industry, there is a constant need for circuit board repair and rework. Whether due to design changes, component failure, or manufacturing defects, restoring and reusing existing printed circuit boards (PCBs) can save significant time and cost. At ACME PCB Assembly, we specialize in providing precise, reliable, and efficient rework and modification services to extend the life of your boards and ensure optimal performance. Custom Rework Solutions for Every Project ACME PCB

-

In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. At Board Assembly, we understand the critical role that a seamless production process plays in bringing innovative products to market swiftly and reliably. That’s why we offer comprehensive full turnkey solutions designed to meet the diverse needs of our clients. These solutions not only streamline the production process but also ensure that every detail is meticulously handled, from initial design to final delivery.

-

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. From smartphones to industrial machinery, PCBs ensure that electrical components are connected and function properly. Whether you’re developing a small prototype or scaling up production, good PCB design practices are critical to success. Here are some expert tips to help you design efficient, high-quality PCBs. 1. Plan Your Layout Strategically The layout of your PCB can make or break your design. Start by organizing

-

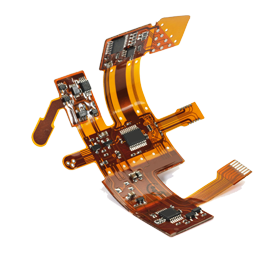

The design rules for flex turnkey PCB assembly is very similar to the design rules for traditional PCBs. Traditional PCBs and flex flex turnkey PCB assembly share some similarities in the manufacturing process as well. To start, the flexible circuit board material (typically copper clad Polyimide) is chosen, drilled, plated, photo-imaged, and imprinted just like the conservative PCB process. Next, both PCBs and flex turnkey PCB assemblies involve the panels being baked to remove any