-

ACME PCB Assembly: A Greenhouse for Sustainable Electronic Manufacturing ACME PCB Assembly is setting a remarkable example of sustainability in electronic manufacturing by leveraging renewable energy. Their solar panel system, which generates 64.2KW, offers incredible environmental benefits. Over the next 30 years, this PV system is projected to offset 4,136,092 pounds of CO2 emissions, reduce particulates linked to asthma by 817 pounds, and equate to taking 21.8 cars off the road for 25 years or

-

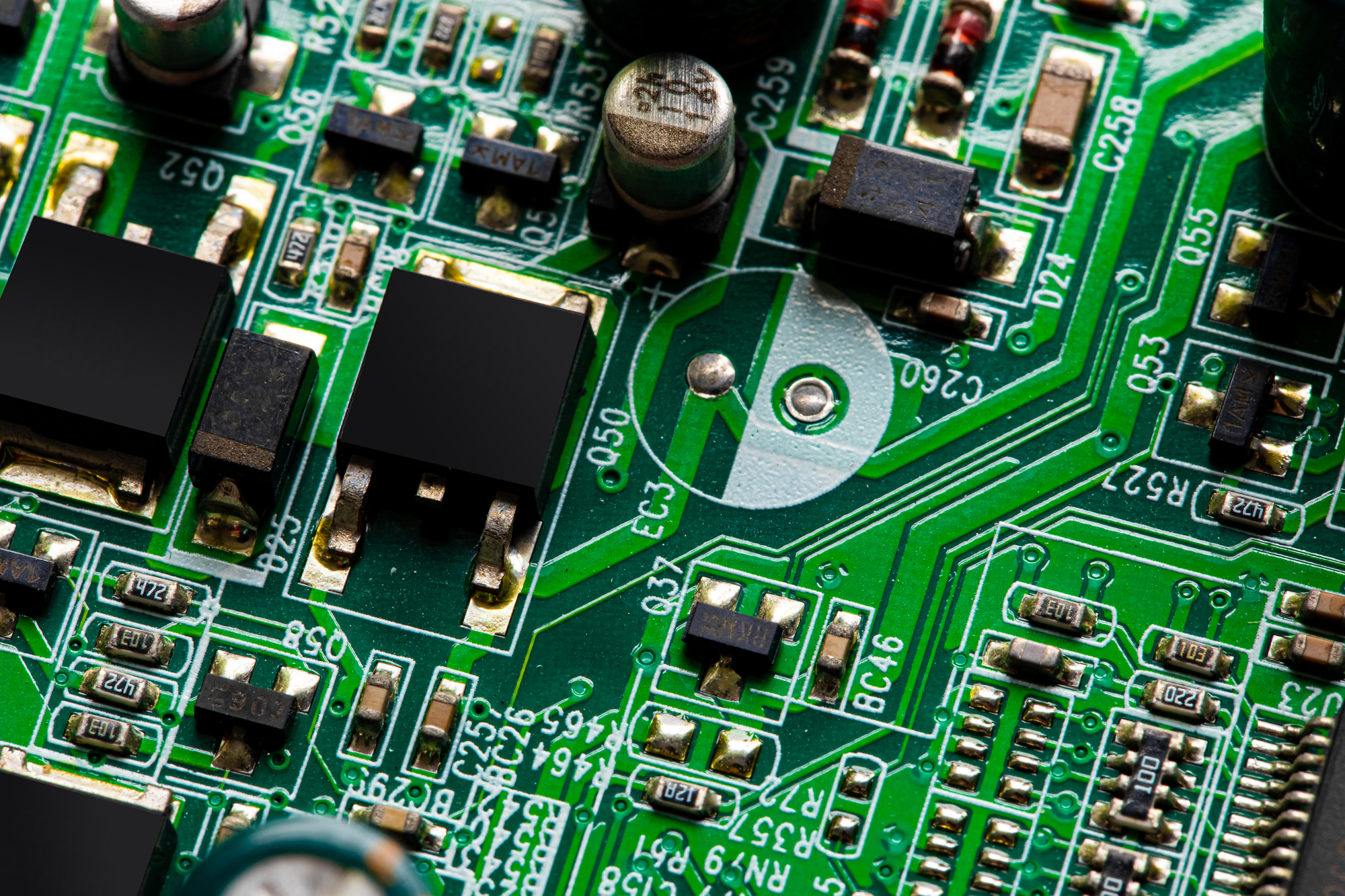

We will be discussing the issue of PCB recycling, if it’s even possible, how it is done and what can we do as electronics design engineers to create more recyclable PCBs. When we say PCB we are meaning a PCB without any components on it. Most electronic devices found out there have their components sitting in a nice looking Printed Circuit Board or PCB. Since electronic devices are in high demand, PCBs are everywhere. Making

-

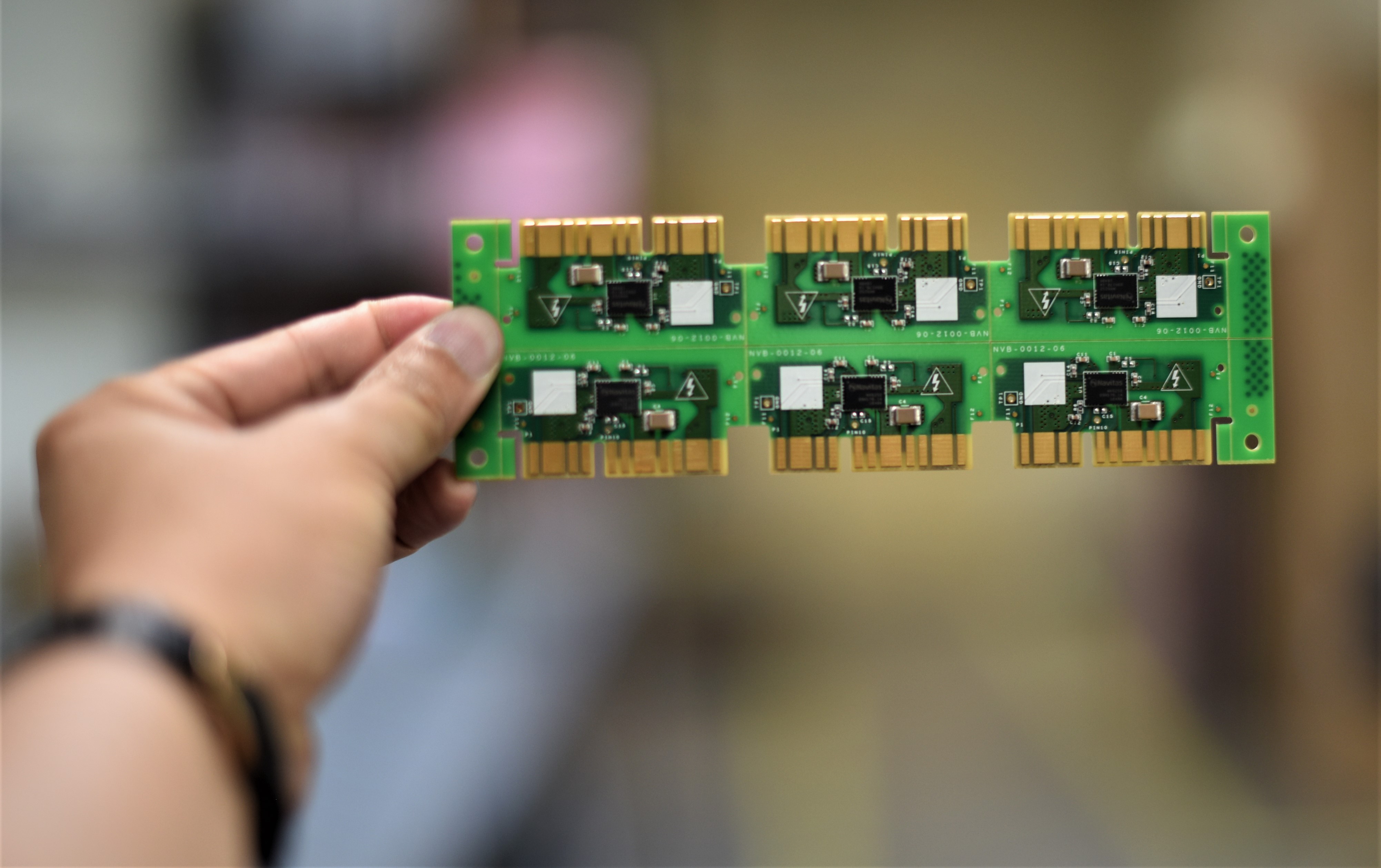

Turn Your Big Idea Into a Prototype Have you been sitting on a great idea, waiting for the perfect moment to bring it to life? As the New Year approaches, many entrepreneurs start planning for growth, innovation, and new business opportunities. If 2026 is the year you want to finally turn your invention into a reality, you’re not alone—and you don’t have to do it by yourself. While creating a new product can seem overwhelming,

-

It is important to understand that a wire harness is different than a cable harness. A wire is a single conductor, while cables are two or more wires that are insulated being wrapped in a larger jacket. These two technologies demand their own set of unique tools, fixtures, and machinery to help reduce production costs. Knowing exactly what type of product being used is crucial to perfectly create your designs. Wire harnesses generally do not

-

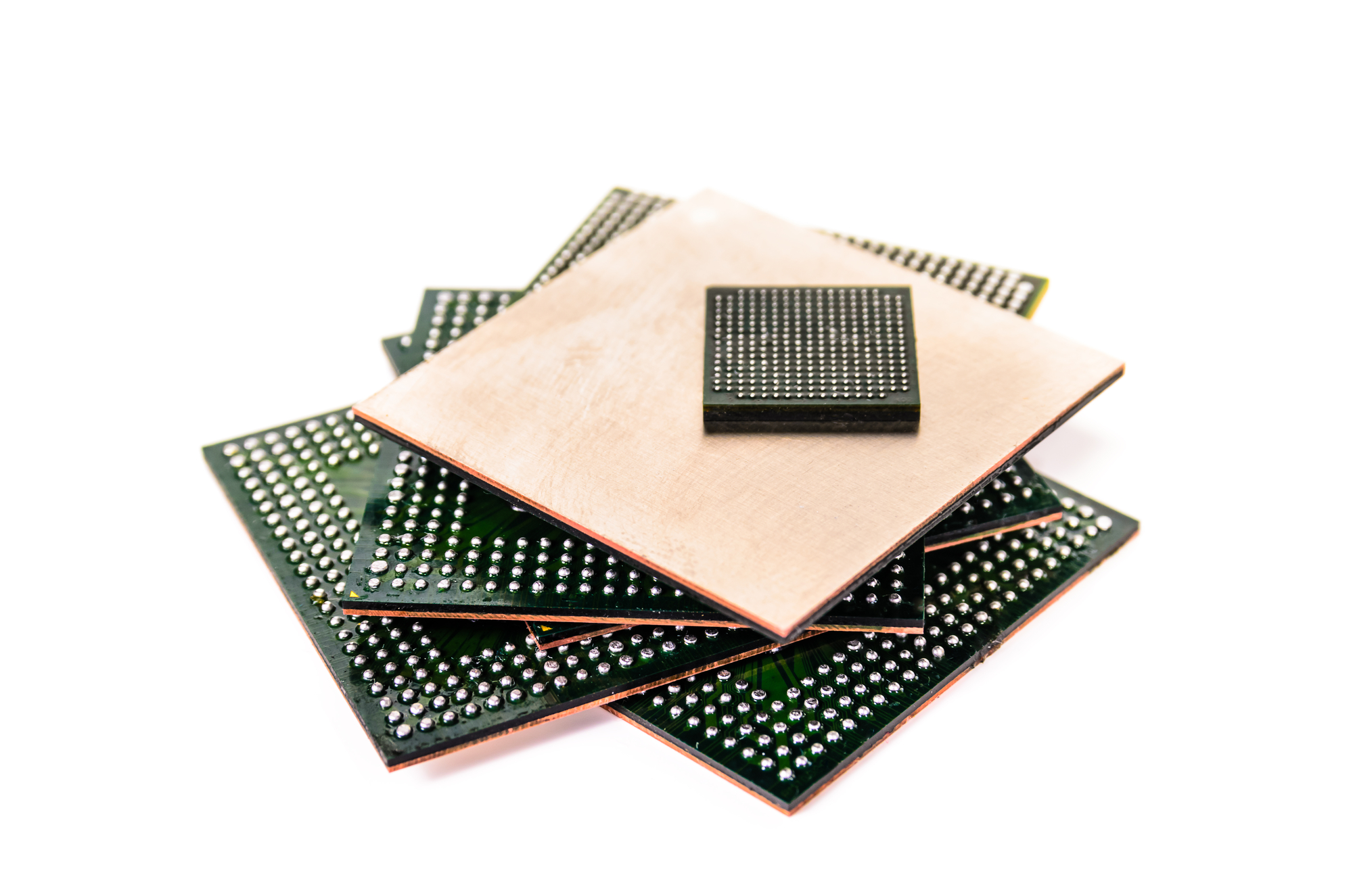

BGA rework, replacement. Board Assembly uses the most powerful tools to maintain the state-of-the-art production. Performance may suffer in mass produced Ball Grid Array (BGA) devices due to many different reasons. Defects in the device, lack of or excess solder joints, or oversights during upgradation processes can be included as one of the may reasons for performance issues. These irregularities can be resolved with BGA rework. We provide a comprehensive BGA rework and re-balling services