ACME PCB assembly is working to meet the growing demand for tabletop “box builds” we have a dedicated team for each department, including covering the purchasing, electronics engineering, contract manufacturing services, and testing.

Our team will support all your electro-mechanical projects from the initial stages of design conception and prototyping through volume production. ACME PCB assembly provides cost-effective turnkey manufacturing solutions to meet your specific project requirements and timeline.

This results in a full turnkey solution to meet your business’s needs. With the continuous development of suppliers from the component level to metal and plastic fabricators has enabled us to meet the most demanding schedules with full PCB assembly, Yun Industrial ACME PCB Assembly also has a clear competitive edge in the total turnkey market.

This results in a full turnkey solution to meet your business’s needs. With the continuous development of suppliers from the component level to metal and plastic fabricators has enabled us to meet the most demanding schedules with full PCB assembly, Yun Industrial ACME PCB Assembly also has a clear competitive edge in the total turnkey market.

What is a Box Build?

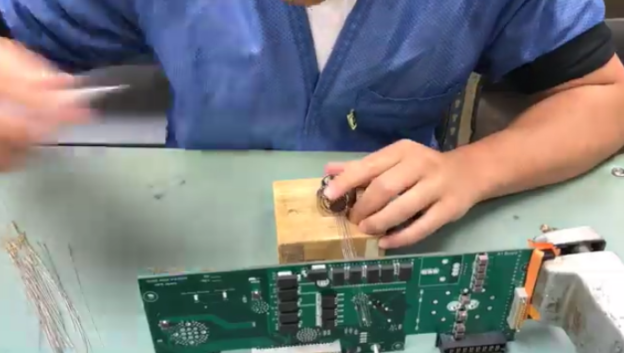

A box build assembly is just like the name says. It involves us assembling various PCB (Printed Circuit Boards) connected through various wiring and with other cables. This process includes PCB fabrication, its installation and then connecting all the components with various wire and cable to get a complete system. This system has many sub-assemblies and lots of other electronic components that are installed in the assembly.

There are many different benefits in using our box build assembly services. One of the main benefits of using this service is to reduce the overall costs while maintaining high-quality control of the system.

PCB box build assembly services are used in many different fields. ACME PCB assembly is known for making reliable, safe and secure box builds. The most common industry where this system is used is the computer industry. But other than the computer industry there are other industries like the medical field, aerospace, telecommunication fields, and many other fields.

Over 25 years in the printed circuit board assembly service business, ACME Printed Circuit Board Assembly knows how to making customer satisfy, check out our Business Hall of Fame Award.

1. Understand Your Application Requirements

1. Understand Your Application Requirements Choosing the right

Choosing the right

Compactness and Efficiency in Medical Technology

Compactness and Efficiency in Medical Technology Supporting the Shift to Digital Healthcare

Supporting the Shift to Digital Healthcare

A box build (also known as system integration or

A box build (also known as system integration or