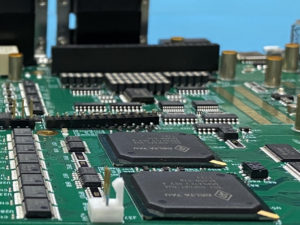

When it comes to bringing an electronic product to market, every component matters—especially the printed circuit board (PCB). At Board Assembly, we specialize in PCB assembly solutions tailored to meet the unique demands of both small and large volume orders. Whether you’re a startup developing your first prototype or an established manufacturer scaling production, having a trusted assembly partner makes all the difference.

Flexible PCB Assembly for Every Project Size

Flexible PCB Assembly for Every Project Size

Not all projects are created equal. Some begin with low-volume runs for testing or proof of concept, while others require full-scale manufacturing to meet demand. We understand the need for flexibility. That’s why our facility is equipped to handle both ends of the spectrum—from a handful of boards to thousands—all while maintaining tight quality control and fast turnaround times.

Startups and small businesses benefit from our low minimum order quantities and personalized service. If you need help with your design or component sourcing, our experienced team is here to assist you at every step. For larger businesses and production-scale orders, we offer automated processes, scalable workflows, and strict adherence to IPC standards.

Quality, Consistency, and Support

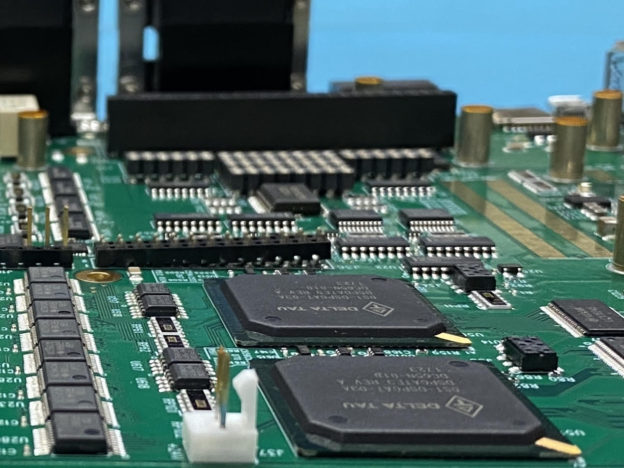

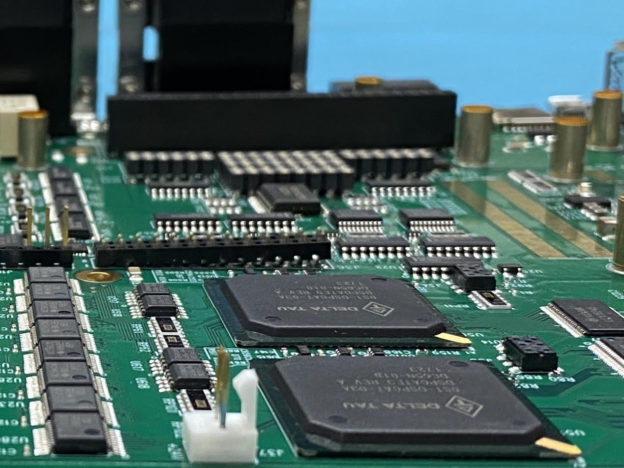

We don’t just assemble circuit boards—we build reliability into your product. Our advanced equipment and trained technicians ensure each board is assembled with precision. Every order, no matter the size, is subjected to rigorous testing and inspection to meet your performance and durability expectations.

Need surface mount (SMT), through-hole, or mixed technology assembly? We’ve got you covered. Our capabilities include both leaded and RoHS-compliant assembly processes, giving you the freedom to choose what’s best for your application and market.

Your Turnkey Partner

At Board Assembly, we go beyond standard manufacturing. From prototype to production, we offer full turnkey solutions including sourcing, assembly, testing, and packaging. This helps streamline your supply chain and gets your product to market faster.

Visit Board Assembly to learn how our PCB assembly services can support your next project—big or small. Contact us today to get started with a quote or design consultation.

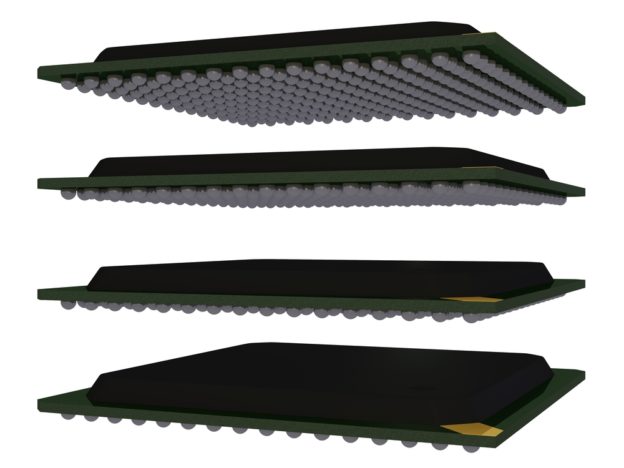

Thermal Performance:

Thermal Performance:

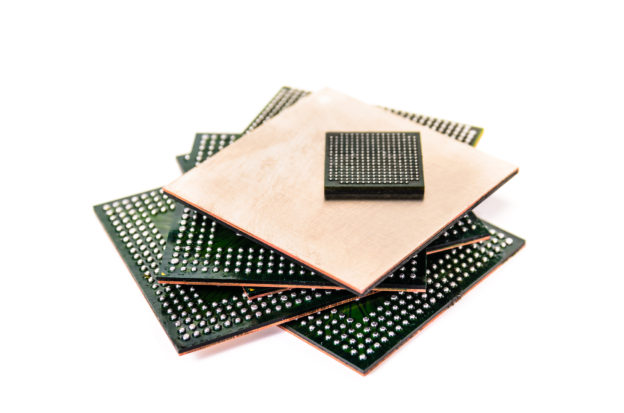

BGA assembly is a type of SMT process, which is used for

BGA assembly is a type of SMT process, which is used for

What Is Turnkey Printed Circuit Board Assembly?

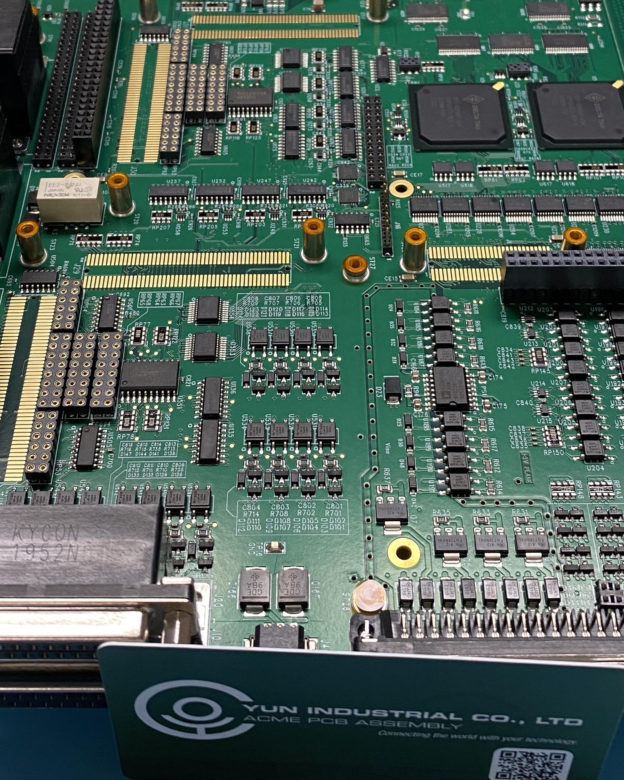

What Is Turnkey Printed Circuit Board Assembly? The ACME PCB Assembly Advantage

The ACME PCB Assembly Advantage

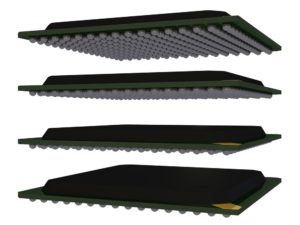

There are two popular configurations for PoP assemblies:

There are two popular configurations for PoP assemblies: