In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. At Board Assembly, we understand the critical role that a seamless production process plays in bringing innovative products to market swiftly and reliably. That’s why we offer comprehensive full turnkey solutions designed to meet the diverse needs of our clients. These solutions not only streamline the production process but also ensure that every detail is meticulously handled, from initial design to final delivery.

Board Assembly’s full turnkey services are built on a foundation of expertise and advanced technology. We start by working closely with our clients during the design phase, ensuring that all specifications are clearly understood and optimized for manufacturability. This collaboration is essential in preventing potential issues later in the production cycle, saving both time and resources.

Board Assembly’s full turnkey services are built on a foundation of expertise and advanced technology. We start by working closely with our clients during the design phase, ensuring that all specifications are clearly understood and optimized for manufacturability. This collaboration is essential in preventing potential issues later in the production cycle, saving both time and resources.

Once the design is finalized, our team takes full responsibility for sourcing all necessary components. We leverage our extensive network of trusted suppliers to obtain high-quality parts that meet exacting standards. This procurement process is a critical aspect of our turnkey offering, as it eliminates the need for clients to manage multiple vendors, thereby reducing complexity and risk.

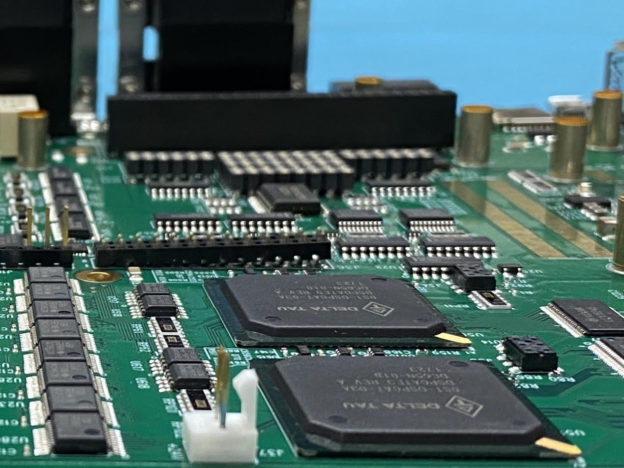

With components in hand, the next stage in our turnkey process is the assembly itself. At Board Assembly, we utilize state-of-the-art equipment and stringent quality control measures to ensure that each board is assembled to the highest standards. Our advanced manufacturing techniques allow us to handle even the most complex assemblies with precision and efficiency.

Testing is another crucial element of our full turnkey solutions. We understand that delivering a product that simply works isn’t enough; it must perform flawlessly in the field. To achieve this, we conduct rigorous testing at every stage of the assembly process. Our testing protocols are designed to catch any potential issues early, ensuring that the final product meets or exceeds all performance requirements.

The final step in our full turnkey process is logistics and delivery. We understand that time is often of the essence, and our streamlined processes are designed to ensure that products are delivered on schedule. Whether it’s a small batch prototype or a large-scale production run, we are committed to meeting deadlines without compromising on quality.

By offering a full turnkey solution, Board Assembly provides our clients with peace of mind, knowing that every aspect of their project is being expertly managed. From the initial design consultation to the final delivery, our team is dedicated to ensuring that your products are built to perform and delivered on time.

For more information about our full turnkey solutions and how they can benefit your next project, visit Board Assembly today.

PCB Prototypes

PCB Prototypes