There is a very good reason why the United States no longer allows lead in paint, plumbing, gasoline, toys, and many household products. Although lead is naturally occurring, it is also a highly toxic metal with serious health consequences. Research has linked lead exposure to behavior and learning difficulties, reduced IQ, slowed growth, anemia, cardiovascular problems, and, in extreme cases, coma or death. Children and pregnant women are especially vulnerable, and even minimal exposure can create long-term neurological and developmental harm.

For many years, lead was widely used in the electronics industry—particularly in soldering printed circuit boards (PCBs). Tin-lead solder was reliable, affordable, and easy to work with, which helped make it the long-standing industry standard. However, as global awareness of lead’s dangers increased, regulators and manufacturers began transitioning toward safer, more environmentally responsible lead-free alternatives.

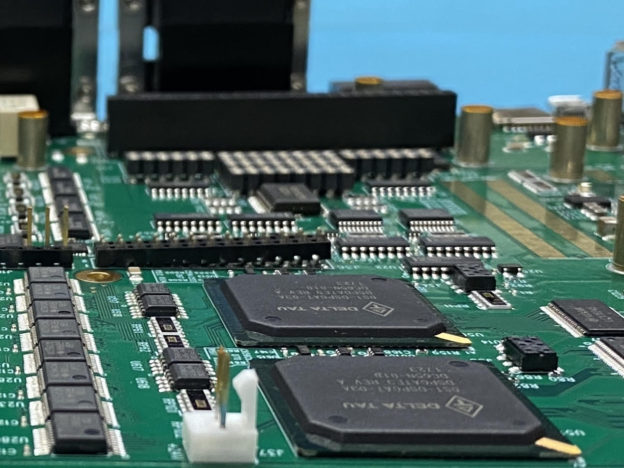

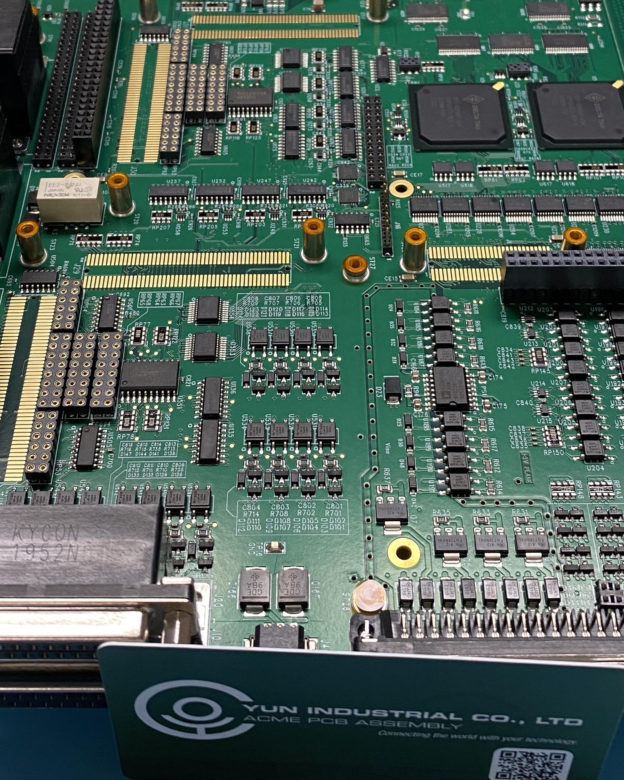

At ACME PCB Assembly, we are proud to be part of this movement. Our full commitment to lead-free PCB assembly ensures a safer environment for employees and a safer end product for our customers. Switching to lead-free soldering is much more complex than simply changing materials. Lead-free solders melt at higher temperatures, which affects the entire assembly process, equipment requirements, and inspection standards.

To meet these demands, we invested in upgraded machinery, re-engineered our soldering and reflow processes, and strengthened temperature control systems to ensure long-term reliability. Just as important, our technicians underwent extensive retraining to understand the different properties, behaviors, and inspection details of lead-free solders. This comprehensive approach allows us to maintain exceptional quality while eliminating a major health and environmental hazard.

To meet these demands, we invested in upgraded machinery, re-engineered our soldering and reflow processes, and strengthened temperature control systems to ensure long-term reliability. Just as important, our technicians underwent extensive retraining to understand the different properties, behaviors, and inspection details of lead-free solders. This comprehensive approach allows us to maintain exceptional quality while eliminating a major health and environmental hazard.

Although the transition required time, investment, and new expertise, it was absolutely worth it. Removing lead from our operations gives us a cleaner, healthier workplace and aligns our manufacturing processes with global standards such as RoHS (Restriction of Hazardous Substances). It also gives our customers confidence that their boards are produced using safe, compliant, and environmentally conscious materials.

Today, ACME PCB Assembly proudly operates as a fully lead-free PCB assembly provider, delivering high-quality, reliable PCBs for industries that demand safety, consistency, and performance. Whether you need prototypes, short production runs, or full-volume assembly, you can count on us to deliver the best results using trusted lead-free technology.

To learn more about our PCB assembly capabilities, please visit:

https://yic-assm.com/pcb-assembly/

When you partner with ACME PCB Assembly, you’re choosing a provider that puts safety, sustainability, and long-term product reliability first.

In the printed circuit board business, there are two primary ways to mount components onto the circuit board:

In the printed circuit board business, there are two primary ways to mount components onto the circuit board:

What Is Turnkey Printed Circuit Board Assembly?

What Is Turnkey Printed Circuit Board Assembly? The ACME PCB Assembly Advantage

The ACME PCB Assembly Advantage

You are looking for a printed circuit board turn-key assembly provider for a new product. When you call up a printed circuit board manufacturer, the first question you are likely to get is, “Do you want full turn key service or partial turn key service?” What is the difference between full and partial turn key service, and what is the best option for you?

You are looking for a printed circuit board turn-key assembly provider for a new product. When you call up a printed circuit board manufacturer, the first question you are likely to get is, “Do you want full turn key service or partial turn key service?” What is the difference between full and partial turn key service, and what is the best option for you? The full turn key service is just like what it sounds. The printed circuit board turn-key assembly provider does all the work. They provide the circuit boards, order all the parts, and fabricate the circuit order. Basically, all you need to do is put in the order. The PCB assembly provider might even be able to help you develop the necessary plans and parts list to get your project off the ground. While a full turn key service will be more expensive than partial turn key service, it can save you a lot of hassle and headaches, especially if you are new to the world of printed circuit boards.

The full turn key service is just like what it sounds. The printed circuit board turn-key assembly provider does all the work. They provide the circuit boards, order all the parts, and fabricate the circuit order. Basically, all you need to do is put in the order. The PCB assembly provider might even be able to help you develop the necessary plans and parts list to get your project off the ground. While a full turn key service will be more expensive than partial turn key service, it can save you a lot of hassle and headaches, especially if you are new to the world of printed circuit boards.