In the ever-evolving landscape of electronics manufacturing, Package on Package (PoP) technology is transforming how circuit boards are designed and assembled. First gaining traction in the early 2000s, PoP is now considered one of the most innovative advances since the introduction of Ball Grid Array (BGA) components in the mid-1990s.

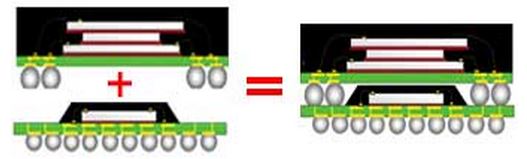

At its core, PoP is an integrated circuit packaging method that vertically stacks two or more BGA packages—typically combining a logic processor and memory component. This space-saving configuration allows for compact, high-performance assemblies ideal for smartphones, wearables, medical devices, and advanced industrial electronics.

The Advantages of PoP Technology

The primary benefit of PoP technology lies in its ability to reduce external pin count through package-level system integration. By stacking chips vertically, engineers can achieve a smaller footprint without sacrificing power or performance. This simplification not only optimizes PCB layout efficiency but also improves overall product reliability by minimizing interconnect lengths and signal interference.

Depending on the configuration, PoP packages can reach a total height as low as 1.4mm, making them perfect for compact devices where every millimeter counts. Additionally, PoP assemblies support independent testing of logic and memory layers, resulting in higher manufacturing yields and easier defect isolation during production.

ACME PCB Assembly: Leading the Way Since 2009

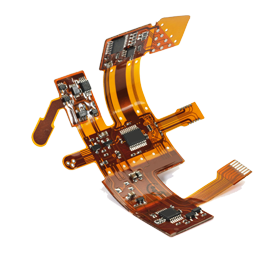

Since 2009, ACME PCB Assembly has been a leader in adopting and refining PoP technology. Utilizing advanced FUJI assembly lines and precise reflow soldering techniques, ACME delivers reliable PoP BGA assemblies for both prototype runs and medium-batch production.

From single-unit builds to production runs of up to 20,000 pieces, ACME’s skilled technicians ensure precise alignment, solder integrity, and quality control at every stage. This allows clients to seamlessly integrate high-density packaging into their next-generation designs—accelerating time to market while maintaining exceptional performance standards.

Whether you’re developing consumer electronics, industrial control systems, or medical devices, PoP technology offers a compact and efficient solution.

Embrace the Future of PCB Assembly

ACME PCB Assembly is your trusted partner for Package on Package assembly, offering experience, precision, and scalability for your most advanced designs. Contact Board Assembly today at 310-715-1898 to learn how PoP can enhance your next project.

Why These Trends Matter for Your Projects

Why These Trends Matter for Your Projects