Turn Your Big Idea Into a Prototype

Have you been sitting on a great idea, waiting for the perfect moment to bring it to life? As the New Year approaches, many entrepreneurs start planning for growth, innovation, and new business opportunities. If 2026 is the year you want to finally turn your invention into a reality, you’re not alone—and you don’t have to do it by yourself. While creating a new product can seem overwhelming, there are experienced companies and manufacturing partners ready to help you through every stage of development.

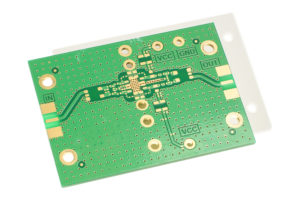

One of the most important steps in bringing any new electronic device to market is completing the prototype phase. A prototype doesn’t just prove that your idea can work; it becomes the foundation for improving your design, testing functionality, pitching investors, and preparing for manufacturing. At ACME PCB Assembly, we specialize in helping inventors, entrepreneurs, and start-ups build the printed circuit boards (PCBs) their products depend on.

One of the most important steps in bringing any new electronic device to market is completing the prototype phase. A prototype doesn’t just prove that your idea can work; it becomes the foundation for improving your design, testing functionality, pitching investors, and preparing for manufacturing. At ACME PCB Assembly, we specialize in helping inventors, entrepreneurs, and start-ups build the printed circuit boards (PCBs) their products depend on.

If you’re unsure about the exact schematics or specifications needed for your PCB design, that’s completely normal. Many innovators come to us with only a concept. Our team guides you from the earliest planning stages through schematic design, PCB layout, and full board assembly. When it comes to the rest of your invention—housing, mechanical components, or product finishing—other vendors can step in to complete your final prototype. ACME’s goal is to ensure that the electronic heart of your device is built correctly, efficiently, and with the quality required for successful testing.

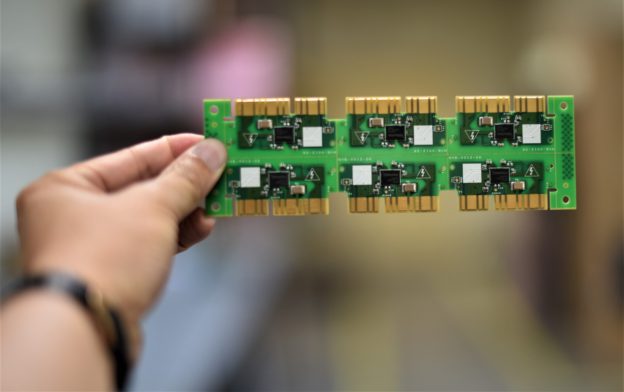

Before long, you’ll have a working prototype in hand—something you can show investors, demonstrate to potential partners, test in real environments, or use to prepare for production. ACME PCB Assembly serves as your reliable resource for prototype Printed Circuit Board Assembly (PCBA). Our certified IPC trainer ensures that every prototype meets industry quality standards. We can assemble boards by hand for low-quantity builds ranging from a single unit up to 50 pieces, ideal for early testing phases.

When you’re ready to scale, ACME PCB Assembly offers smooth transition into higher-volume production. Our FUJI SMT pick-and-place line allows us to handle runs from 1-piece prototypes up to 10,000-piece production batches. Few PCB partners offer such flexibility, making ACME the ideal choice for both early-stage innovators and growing companies.

ACME provides a complete suite of PCB Assembly Services, including SMT, Through-Hole, BGA, rework, lead-free assembly, turnkey solutions, and more. We also offer additional manufacturing support such as Injection Molding and Metal Work & Finishing—giving clients access to an end-to-end approach when preparing their products for market.

We provide a complete suite of PCB Assembly Services, including rework and modification, BGA, SMT, Turnkey, Thru-Hole, Lead Free, and Prototype assembly, plus an extensive line of add-on services, such as Injection Molding and Metal Work & Finishing. ACME PCB Assembly has been providing Electronic Manufacturing Services (EMS) and Printed Circuit Board (PCB) assembly for 27 years.

Ready to turn your idea into a prototype? Visit our PCB assembly service page and get started today:

Contact us today to get started prototyping the printed circuit boards you need.