In today’s competitive electronics industry, businesses of all sizes depend on electronic manufacturing services (EMS) to transform innovative designs into reliable, market-ready products. An EMS provider handles critical stages of production — from prototype assembly to mass-scale manufacturing — allowing companies to focus on design, marketing, and growth while leaving complex manufacturing details in expert hands.

Electronic Manufacturing Services encompass a wide array of capabilities, including PCB assembly, testing, procurement, and post-production support. By partnering with a full-service EMS provider like BoardAssembly, companies benefit from experienced manufacturing expertise that addresses technical challenges and reduces time to market.

Early in the product lifecycle, EMS providers support design for manufacturability (DFM) reviews. In this phase, engineers analyze PCB layouts and specifications to identify potential assembly issues, suggest improvements, and ensure components are optimized for manufacturing. This proactive approach minimizes costly revisions and improves end-product quality.

Early in the product lifecycle, EMS providers support design for manufacturability (DFM) reviews. In this phase, engineers analyze PCB layouts and specifications to identify potential assembly issues, suggest improvements, and ensure components are optimized for manufacturing. This proactive approach minimizes costly revisions and improves end-product quality.

Once a design is manufacturing-ready, the EMS provider manages component sourcing and supply chain logistics, securing parts from reputable vendors and mitigating shortages or long lead times. Strategic sourcing is especially valuable in today’s fluctuating global market, where procurement disruptions can delay production schedules.

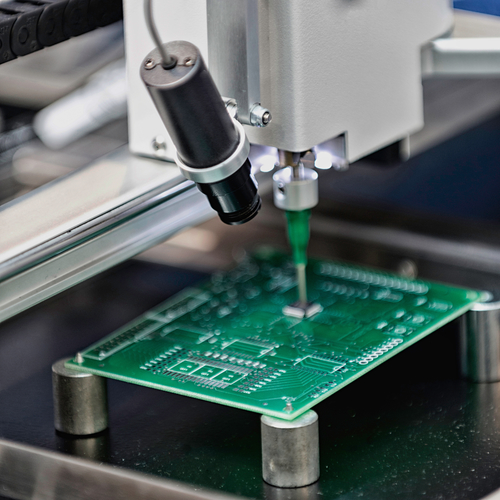

PCB assembly is at the core of EMS offerings. Whether your project uses surface mount (SMT), thru-hole, or a combination of technologies, an experienced EMS partner delivers precision assembly and thorough inspection. BoardAssembly’s services include BGA assembly, thru-hole assembly, and advanced soldering techniques to support diverse component types and complex designs.

In addition to assembly, EMS providers implement stringent quality control and testing procedures, ensuring each product meets performance requirements and industry standards. Functional testing, in-circuit testing, and inspection tools like AOI (Automated Optical Inspection) help catch defects early, reducing returns and warranty claims.

For businesses aiming for a complete solution, EMS often includes turnkey assembly, where the provider manages all aspects of production — from design review through final delivery. This hands-off model streamlines operations and often improves cost efficiency through economies of scale and process optimization.

Beyond initial production, top EMS partners offer scalability for growth as demand increases. Whether moving from small-scale runs to full production or supporting redesigns and upgrades, EMS providers like BoardAssembly deliver flexible manufacturing services that keep pace with evolving business needs.

In summary, electronic manufacturing services are a cornerstone of modern electronics product development and production. By leveraging EMS expertise, companies reduce risks, improve quality, and bring innovations to market faster and more efficiently. Explore how EMS can advance your product goals by visiting https://boardassembly.com/ems/.