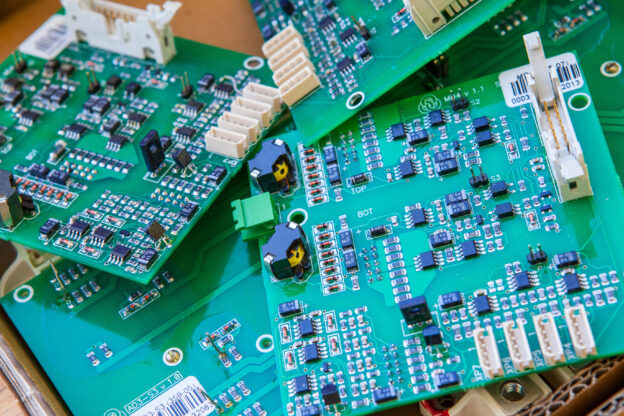

In the world of printed circuit board (PCB) manufacturing, thru-hole assembly services remain a critical choice for projects demanding strength, durability, and reliability. While surface mount technology (SMT) often dominates discussions about electronics assembly, thru-hole assembly has unique benefits that make it indispensable for certain applications — especially in industrial, aerospace, automotive, and defense systems where component permanence and mechanical integrity are essential.

Thru-hole assembly involves inserting electronic component leads into drilled holes on a PCB and soldering them in place. This process creates mechanically robust solder joints, superior to many surface mount options when it comes to withstanding vibration and thermal stress. Industries that demand long-life performance and high reliability often favor thru-hole components like connectors, large capacitors, transformers, and tall leaded components that simply cannot be mounted using SMT alone.

Thru-hole assembly involves inserting electronic component leads into drilled holes on a PCB and soldering them in place. This process creates mechanically robust solder joints, superior to many surface mount options when it comes to withstanding vibration and thermal stress. Industries that demand long-life performance and high reliability often favor thru-hole components like connectors, large capacitors, transformers, and tall leaded components that simply cannot be mounted using SMT alone.

Choosing an expert provider of thru-hole assembly ensures consistent quality and performance. BoardAssembly’s dedicated team specializes in integrating thru-hole techniques with modern manufacturing controls, delivering assemblies that meet stringent quality standards. Whether your project requires selective soldering, manual insertion, or hybrid assembly workflows, a trusted partner with experience across technologies is vital.

One major advantage of thru-hole assembly is its compatibility with automated wave soldering — a highly efficient soldering process for large volumes of boards with thru-hole components. When paired with thorough inspection and process controls, wave soldering enhances throughput while maintaining consistency.

Despite its strengths, thru-hole assembly is often used alongside SMT in a mixed technology assembly environment. Most advanced electronic systems leverage both technologies: SMT for dense, fine-pitch parts and thru-hole for components requiring solid mechanical support. BoardAssembly understands how to balance these techniques within a single PCB assembly workflow to optimize performance and cost.

To further support complete electronics manufacturing solutions, BoardAssembly also offers comprehensive services including EMS (Electronic Manufacturing Services) and turnkey assembly, creating seamless results from prototype to full production. By combining expert thru-hole assembly with strategic manufacturing planning, customers gain faster time to market and fewer production delays.

For designers and engineers, early collaboration with your assembly partner on DFM (Design for Manufacturability) feedback is essential. Proactive analysis during the design phase reduces risks and ensures that thru-hole components are placed and oriented for efficient assembly and long-term functionality.

In summary, thru-hole assembly remains a valuable and relevant process within modern PCB production — especially when executed by experienced professionals with access to advanced tools and quality systems. Integrating thru-hole services into your next PCB build can enhance strength, reliability, and overall product performance.

Learn more about industry-leading thru-hole assembly services at https://boardassembly.com/thru-hole-assembly/.