Often times, people who are not strictly linked with metal works fields, can confuse between the sheet metal punching and the sheet metal stamping.

This happens because, at first glance, the meaning of these two words might seem the same. On the contrary, the sheet metal punching and the stamping are really different starting from the equipment required to achieve punching and stamping.

This happens because, at first glance, the meaning of these two words might seem the same. On the contrary, the sheet metal punching and the stamping are really different starting from the equipment required to achieve punching and stamping.

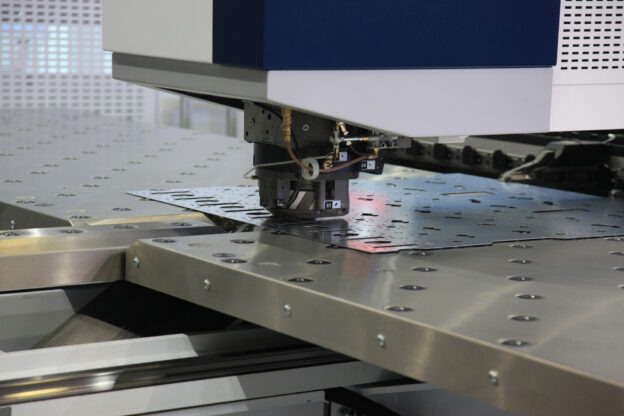

The first ones, are metal forming processes realized with automatic CNC machines that use punch presses and dies realizing any kind of hole. The punch pass through the sheet metal while the dies, located on the other side of the metal piece, work as support and help punches to put more force ensuring the non-breaking of metal.

Otherwise, the stamping is the set of operations performed to obtain specific shapes and it includes our sheet metal punching. Stamping is in fact a consequence of others metal processes such as punching, blanking, sheet metal deep-drawing and bending. It’s the ending process useful for giving to metal pieces a specific shape to the entire piece.

To be clear, there’s a third metal process which often is confused and it’s called pressing. The metal pressing, contrary to the sheet metal punching is processed to give shape without breaking the metal piece. For example, pressing process is used to realize corners.