-

In today’s competitive electronics industry, businesses of all sizes depend on electronic manufacturing services (EMS) to transform innovative designs into reliable, market-ready products. An EMS provider handles critical stages of production — from prototype assembly to mass-scale manufacturing — allowing companies to focus on design, marketing, and growth while leaving complex manufacturing details in expert hands. Electronic Manufacturing Services encompass a wide array of capabilities, including PCB assembly, testing, procurement, and post-production support. By partnering

-

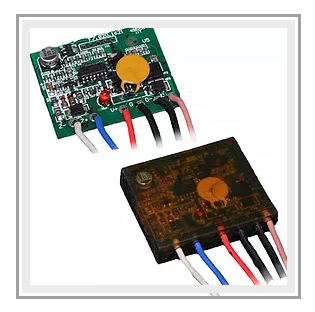

When electronic assemblies are exposed to moisture, chemicals, vibration, dust, or extreme temperature fluctuations, ordinary protection simply isn’t enough. Sensitive components require a higher level of defense to maintain long-term reliability. Potting and encapsulation services provide some of the most robust environmental protection available by fully surrounding electronic assemblies with epoxy, silicone, or urethane compounds. At Board Assembly, we specialize in delivering professional, application-specific potting and encapsulation solutions designed to improve performance and extend the

-

As electronic products become more advanced and integrated, companies increasingly rely on professional box build assembly services to streamline production, improve consistency, and reduce internal labor demands. A box build encompasses everything beyond PCB assembly and involves assembling the complete electromechanical system. This includes wiring, enclosure installation, cable routing, labeling, programming, software loading, testing, and final integration. Board Assembly provides turnkey box build solutions designed to support prototypes, low-volume manufacturing, and fully scaled production environments.

-

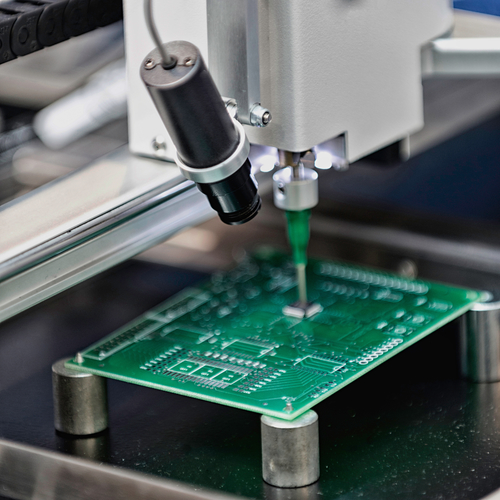

As electronic devices become smaller, more complex, and more widely used across harsh environments, protecting the internal circuitry becomes essential. Conformal coating is one of the most effective ways to safeguard printed circuit boards from moisture, corrosion, dust, vibration, and chemical exposure. At Board Assembly, our conformal coating services provide long-lasting environmental protection for PCBs used in industrial, medical, commercial, and aerospace applications. Conformal coating is applied as a thin polymer layer—usually acrylic, silicone, epoxy,

-

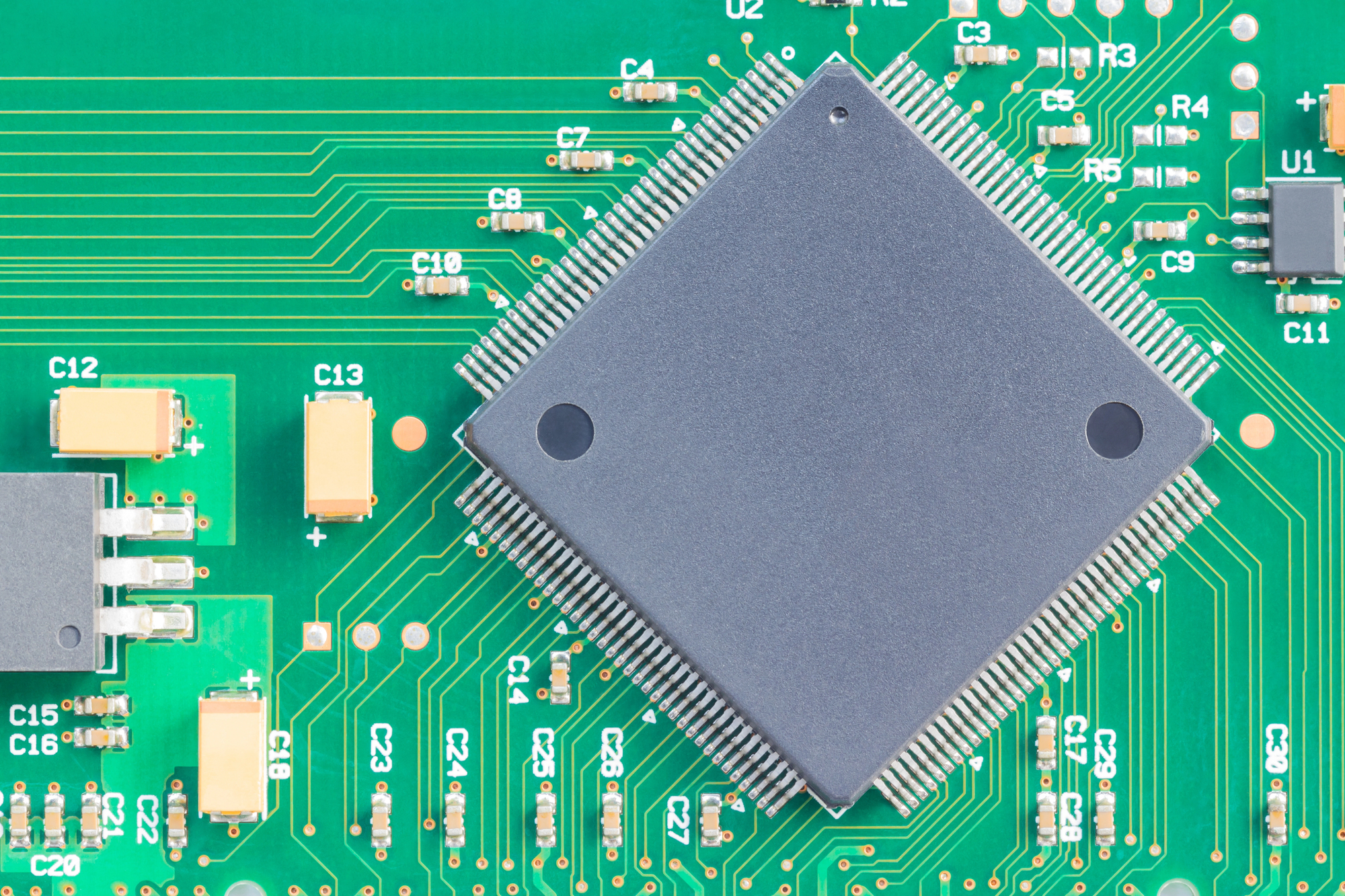

Surface Mount Technology (SMT) has become the backbone of modern electronics manufacturing, enabling compact designs, higher component density, and superior electrical performance. At Board Assembly, we provide advanced SMT assembly services designed for prototype development, small-batch runs, and full-scale production. Our expertise, state-of-the-art equipment, and commitment to quality ensure your printed circuit boards meet the highest industry standards. SMT assembly involves placing miniature components directly onto the PCB surface without the need for drilled holes.