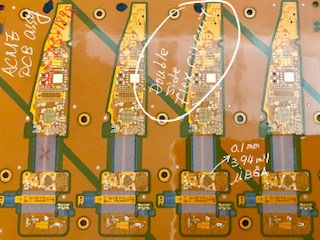

There are many benefits of uBGA Assembly on Double Sided Flex Circuit Board offered by the Acme PCB Assembly, beginning with the fact it can considerably improve the physical characteristics of a design by reducing both weight and size. The cost and performance advantages of using uBGA Assembly on Double Sided Flex Circuit Boards are also quality points that engineers and designers keep in mind, since this technology is used in many types of industries.

ACCURATE, EFFICIENT uBGA ASSEMBLY ON DOUBLE SIDED FLEX CIRCUIT BOARD

A correctly constructed uBGA assembly on double sided flexible circuit board is at the heart of many successful product production operations. Flexible Circuit board assembly and design is a complex, specialized process, which is why many companies choose to outsource this task to a PCB assembly provider that has the capability to get the job done properly and promptly. If you need high-grade uBGA Assembly on flexible printed circuit board that results in a high-performance solution to your manufacturing requirements, Acme PCB Assembly can help.

If you need help with Ball Grid Array (BGA/uBGA) assembly on a double sided flex circuit boards contact us today and we can give you a quote for your next project.

DOUBLE SIDED FLEX CIRCUIT BOARD PERFORMANCE VS RIGID PCB

- Superior heat dissipation.

- Dynamic Flexing.

- Lower inductance (vs traditional wiring systems).

- Superior package density.

PRINTED CIRCUIT BOARD ASSEMBLY COMPANY TO MEET YOUR DEADLINES

PRINTED CIRCUIT BOARD ASSEMBLY COMPANY TO MEET YOUR DEADLINES

ACME PCB Assembly uses the most advanced equipment for the development and manufacturing of high performance uBGA Assembly on Double Sided Flex Circuit Board . ACME PCB Assembly has equipment and processes which allow us to offer our customers a flexible, cost-effective, and quality-focused assembly. ACME understands the challenges companies face for their projects. ACME Flexible PCB Assembly is able to accommodate large orders while getting the work done within the the time expected.

To find out more, call us at 310-715-1898

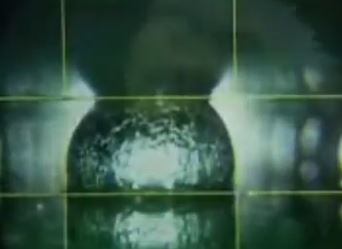

Instead of using pins like traditional packages, a BGA uses an array of solder balls on the underside of the component. These balls create electrical connections during reflow soldering, improving both thermal conductivity and electrical performance. The result is a more robust, space-efficient, and reliable PCB assembly.

Instead of using pins like traditional packages, a BGA uses an array of solder balls on the underside of the component. These balls create electrical connections during reflow soldering, improving both thermal conductivity and electrical performance. The result is a more robust, space-efficient, and reliable PCB assembly.

The

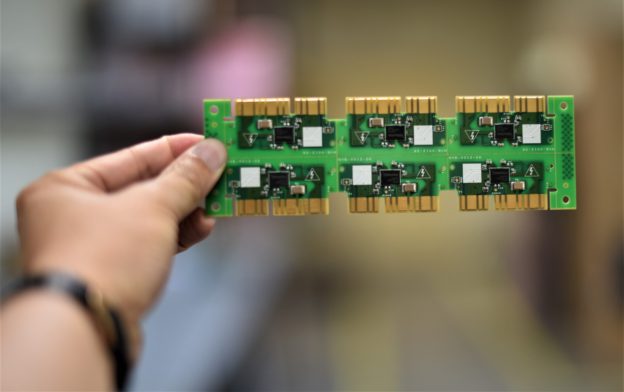

The  Adding the silkscreen is typically the final step in PCB fabrication, done while the boards are still panelized. The ink used must be carefully chosen to withstand the chemicals and heat involved in soldering and assembly. Once printed, the board moves to the final finishing or routing phase.

Adding the silkscreen is typically the final step in PCB fabrication, done while the boards are still panelized. The ink used must be carefully chosen to withstand the chemicals and heat involved in soldering and assembly. Once printed, the board moves to the final finishing or routing phase. Trust ACME PCB for Quality PCB Manufacturing

Trust ACME PCB for Quality PCB Manufacturing

What Is a PCB, Really?

What Is a PCB, Really? What Electronics Design Engineers Can Do

What Electronics Design Engineers Can Do