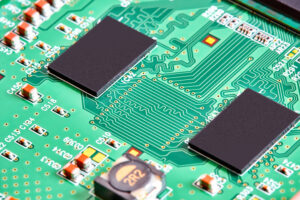

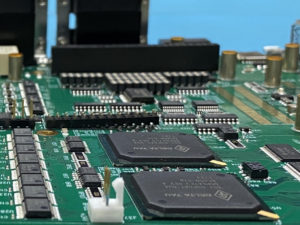

Surface Mount Technology (SMT) has become the backbone of modern electronics manufacturing, enabling compact designs, higher component density, and superior electrical performance. At Board Assembly, we provide advanced SMT assembly services designed for prototype development, small-batch runs, and full-scale production. Our expertise, state-of-the-art equipment, and commitment to quality ensure your printed circuit boards meet the highest industry standards.

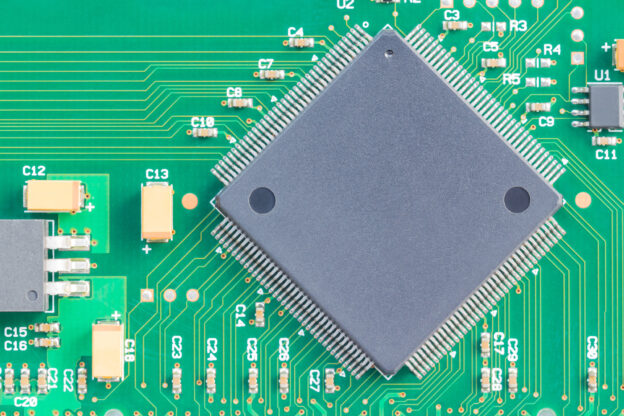

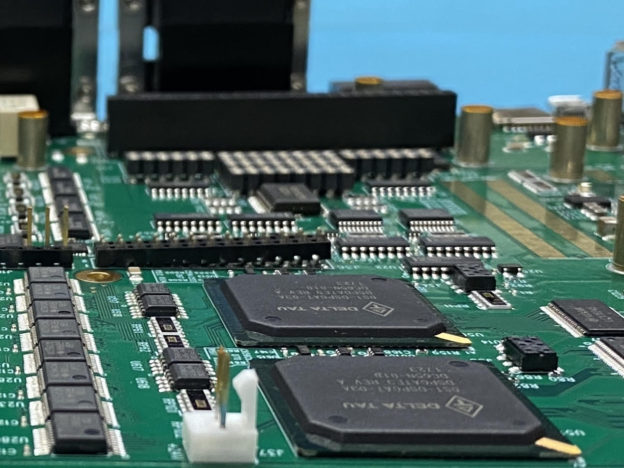

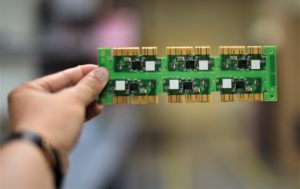

SMT assembly involves placing miniature components directly onto the PCB surface without the need for drilled holes. This allows for faster manufacturing, reduced board size, and the ability to integrate complex circuitry into smaller devices. At Board Assembly, our automated pick-and-place SMT machines provide exceptional accuracy, ensuring precise positioning of even the smallest components such as micro-BGAs, 01005 packages, and high-pin-count ICs.

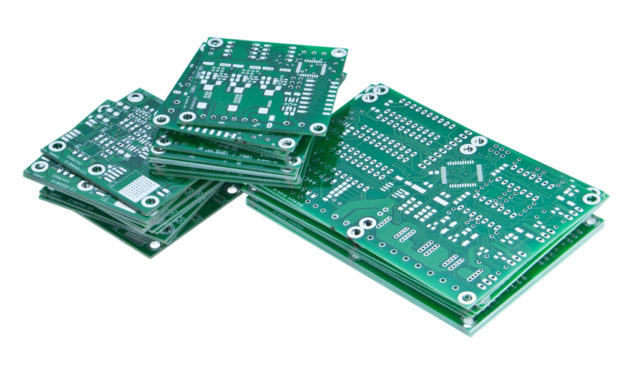

For every project, we begin with a thorough design and documentation review to ensure manufacturability. Our engineering team evaluates your Gerber files, BOM, and assembly drawings to verify compatibility with our SMT processes. This helps prevent redesign costs, minimize delays, and ensure seamless transition from prototype to production.

Once the assembly begins, solder paste is applied using tightly controlled stencil printing methods. This ensures proper solder volume, which is critical for component adhesion and long-term performance. Our automated reflow ovens use multi-zone temperature profiling to ensure consistent solder joints across every PCB. Whether your project requires leaded or RoHS-compliant lead-free soldering, Board Assembly adheres to strict temperature controls that guarantee reliability.

Once the assembly begins, solder paste is applied using tightly controlled stencil printing methods. This ensures proper solder volume, which is critical for component adhesion and long-term performance. Our automated reflow ovens use multi-zone temperature profiling to ensure consistent solder joints across every PCB. Whether your project requires leaded or RoHS-compliant lead-free soldering, Board Assembly adheres to strict temperature controls that guarantee reliability.

Quality assurance is a core part of our SMT assembly workflow. Every PCB undergoes AOI inspection, verifying solder joints, polarity, bridging, component alignment, and placement accuracy. For boards with hidden joints like BGAs, we perform X-ray inspection to evaluate internal connections. These extra steps ensure long-term durability and minimize field failure risks.

Whether you are developing medical devices, IoT solutions, consumer products, industrial equipment, or aerospace electronics, our SMT assembly capabilities support a wide range of applications. Combined with our additional services—such as conformal coating, box build assembly, and potting & encapsulation—we offer complete turnkey solutions to support your entire production lifecycle.

Learn more about our SMT capabilities at:

https://boardassembly.com/smt-assembly/

Unfortunately, many companies—especially those importing parts or outsourcing overseas—skip the trial run because they are pressed for time or eager to deliver products to their customers. However, bypassing this stage can result in:

Unfortunately, many companies—especially those importing parts or outsourcing overseas—skip the trial run because they are pressed for time or eager to deliver products to their customers. However, bypassing this stage can result in:

The journey from concept to finished product begins with one of the most crucial stages in development: New Product Introduction (NPI). NPI is where your idea becomes a structured plan, your design becomes tangible, and your vision starts taking shape. It covers everything from planning and engineering to prototyping and testing—steps that ultimately determine your product’s success.

The journey from concept to finished product begins with one of the most crucial stages in development: New Product Introduction (NPI). NPI is where your idea becomes a structured plan, your design becomes tangible, and your vision starts taking shape. It covers everything from planning and engineering to prototyping and testing—steps that ultimately determine your product’s success. Make 2026 Your Year of Innovation

Make 2026 Your Year of Innovation

To meet these demands, we invested in upgraded machinery, re-engineered our soldering and reflow processes, and strengthened temperature control systems to ensure long-term reliability. Just as important, our technicians underwent extensive retraining to understand the different properties, behaviors, and inspection details of lead-free solders. This comprehensive approach allows us to maintain exceptional quality while eliminating a major health and environmental hazard.

To meet these demands, we invested in upgraded machinery, re-engineered our soldering and reflow processes, and strengthened temperature control systems to ensure long-term reliability. Just as important, our technicians underwent extensive retraining to understand the different properties, behaviors, and inspection details of lead-free solders. This comprehensive approach allows us to maintain exceptional quality while eliminating a major health and environmental hazard.

PCB production is traditionally resource-intensive. It requires large amounts of raw materials, water, energy, and chemical processing. Without proactive sustainability efforts, these processes can contribute to carbon emissions, hazardous waste, and long-term environmental damage. At the same time, many OEMs and end users now demand greener supply chains. Regulatory pressure is increasing, and corporate responsibility expectations are higher than ever. Sustainable PCB manufacturing is now essential to long-term business success and global environmental stewardship.

PCB production is traditionally resource-intensive. It requires large amounts of raw materials, water, energy, and chemical processing. Without proactive sustainability efforts, these processes can contribute to carbon emissions, hazardous waste, and long-term environmental damage. At the same time, many OEMs and end users now demand greener supply chains. Regulatory pressure is increasing, and corporate responsibility expectations are higher than ever. Sustainable PCB manufacturing is now essential to long-term business success and global environmental stewardship. By selecting a manufacturer committed to sustainable production, businesses take an active role in protecting the environment without sacrificing performance or reliability.

By selecting a manufacturer committed to sustainable production, businesses take an active role in protecting the environment without sacrificing performance or reliability.