-

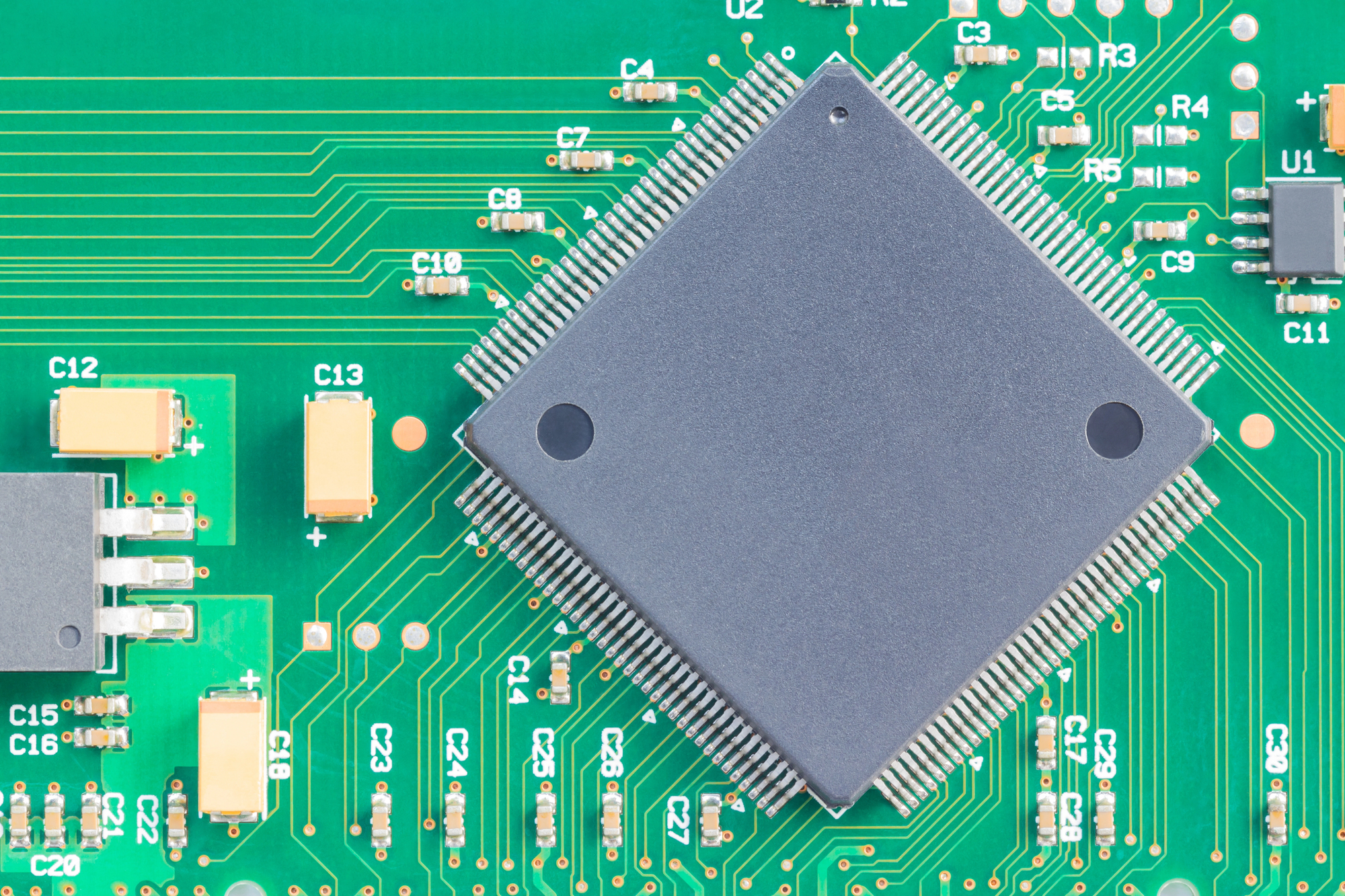

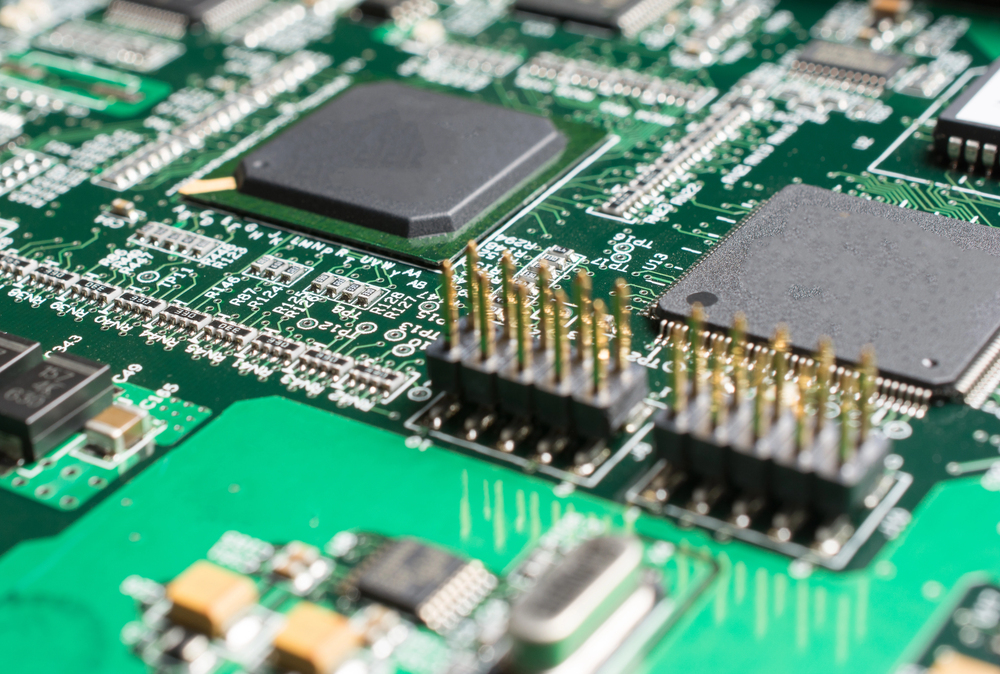

Surface Mount Technology (SMT) has become the backbone of modern electronics manufacturing, enabling compact designs, higher component density, and superior electrical performance. At Board Assembly, we provide advanced SMT assembly services designed for prototype development, small-batch runs, and full-scale production. Our expertise, state-of-the-art equipment, and commitment to quality ensure your printed circuit boards meet the highest industry standards. SMT assembly involves placing miniature components directly onto the PCB surface without the need for drilled holes.

-

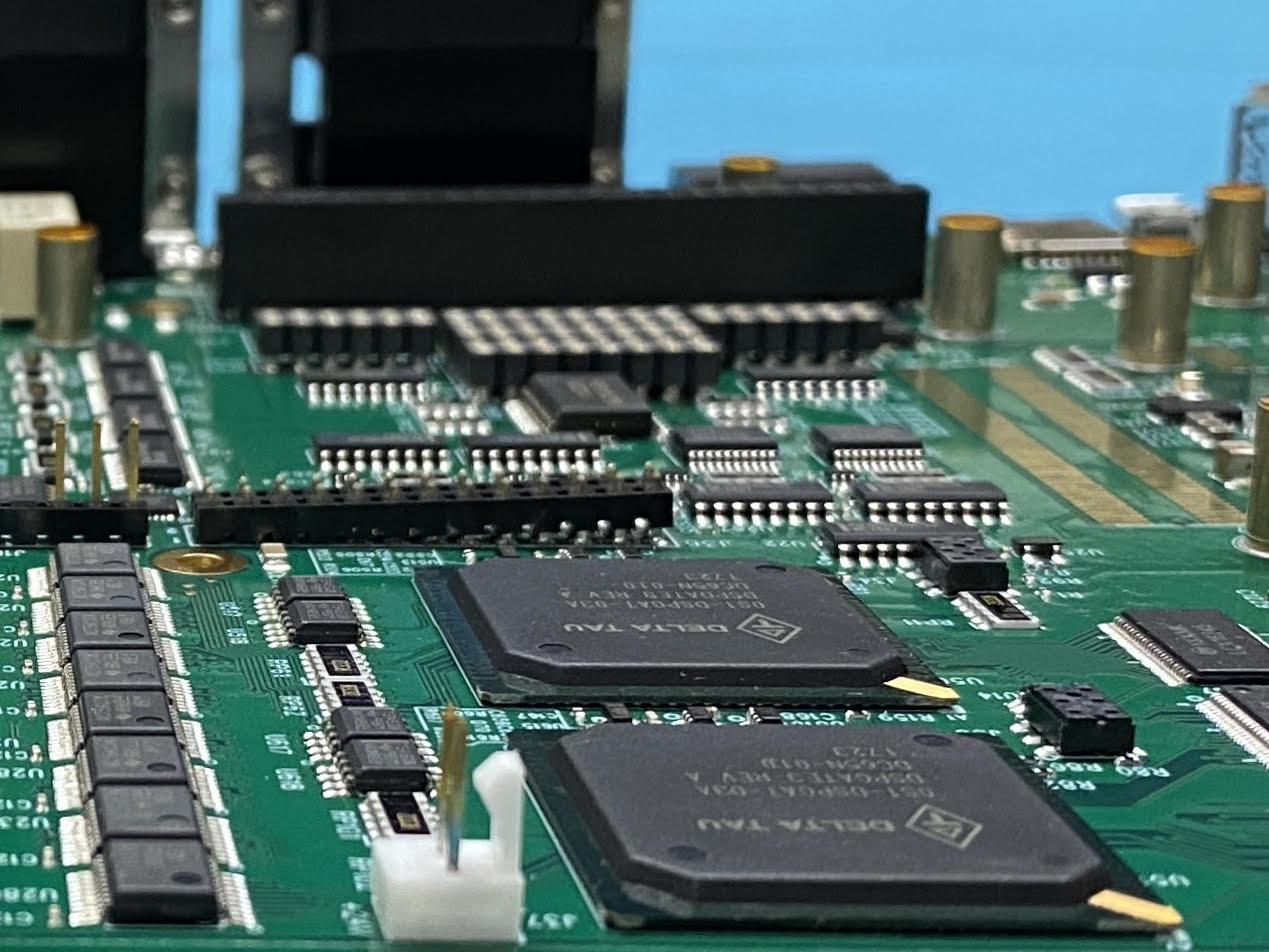

In today’s electronics market, circuitry design and PCB layout play a critical role in product performance, reliability, and manufacturability. As devices become smaller and more complex, many companies choose to outsource PCB design services rather than manage the process entirely in-house. Outsourcing PCB layout and design is not just a cost decision—it’s a strategic move that improves efficiency, quality, and speed to market. What Does Outsourcing PCB Design Mean? Outsourcing can be defined as the

-

Do you have a new PCB idea that you’re excited to bring to life? Once your design is finalized and ready for production, it’s tempting to jump straight into a large manufacturing order—especially if you believe the product will sell quickly. But before committing to thousands of units, there’s a far more important question to ask: Will the PCB actually work the way you expect once produced in large quantities? This is exactly why PCB

-

Have you been sitting on an invention idea, waiting for the perfect moment to turn it into a real product? With 2026 right around the corner, now is the ideal time to take action. Whether you’re an entrepreneur, inventor, engineer, or startup founder, this can be the year you bring your idea out of your head and into the marketplace. And the best part? You don’t have to do it alone. The journey from concept

-

There is a very good reason why the United States no longer allows lead in paint, plumbing, gasoline, toys, and many household products. Although lead is naturally occurring, it is also a highly toxic metal with serious health consequences. Research has linked lead exposure to behavior and learning difficulties, reduced IQ, slowed growth, anemia, cardiovascular problems, and, in extreme cases, coma or death. Children and pregnant women are especially vulnerable, and even minimal exposure can