We will be discussing the issue of PCB recycling, if it’s even possible, how it is done and what can we do as electronics design engineers to create more recyclable PCBs. When we say PCB we are meaning a PCB without any components on it. Most electronic devices found out there have their components sitting in a nice looking Printed Circuit Board or PCB. Since electronic devices are in high demand, PCBs are everywhere. Making sure their materials can be collected and reused instead of just throwing them into a landfill would potentially be a smart and environmentally sensible move if performed properly.

Remember that large order of printed circuit boards you ordered? You thought it would be a good idea to have a surplus of parts on hand in case you needed to increase production of your product line. Unfortunately, that product got discontinued, so now you have a huge stash of PCBs taking up room in your warehouse and on your accounting books. It is time to trash them?

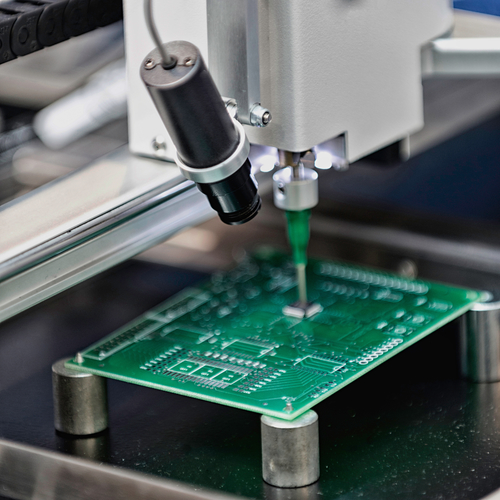

Not so fast! In many cases, printed circuit boards can be reworked and modified. Do you have another electronic or computerized product in the works? Then contact ACME PCB Assembly we may be able to re-purpose your PCBs. Our workers are highly trained in de-soldering and re-soldering surface mounted electronic components. We have also invested in specialized equipment that can assist us in these efforts.

Can you recycle your old PCB?

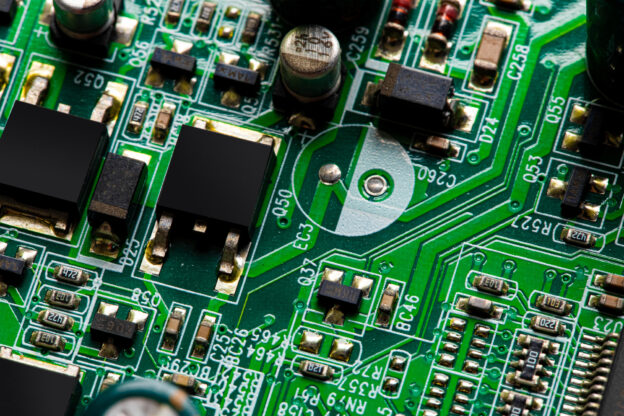

Yes and no, before coming to a final decision let’s first see what a PCB is made of. A PCB is basically a layered sandwich of copper and FR-4. FR-4 is a fiberglass with an epoxy resin that has the purpose of bonding the fiber together and as an adhesive, it is also flame resistant. Apart from that, you can also find tin and small traces of gold and silver.

Don’t throw out unused printed circuit boards.