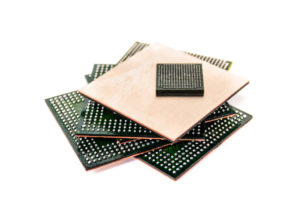

A Ball Grid Array (BGA) is a type of Surface Mount Technology (SMT) packaging widely used for integrated circuits (ICs) that require a large number of interconnects. BGA packaging allows for a compact, high-density design, enabling the integration of more functions on a single chip module—making it an essential component in today’s modern electronics.

What Makes BGA Technology So Effective?

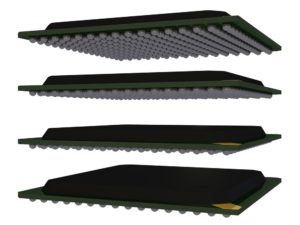

Instead of using pins like traditional packages, a BGA uses an array of solder balls on the underside of the component. These balls create electrical connections during reflow soldering, improving both thermal conductivity and electrical performance. The result is a more robust, space-efficient, and reliable PCB assembly.

Instead of using pins like traditional packages, a BGA uses an array of solder balls on the underside of the component. These balls create electrical connections during reflow soldering, improving both thermal conductivity and electrical performance. The result is a more robust, space-efficient, and reliable PCB assembly.

Key advantages of BGA packaging include:

-

Reduced board thickness – ideal for smartphones, tablets, and compact electronics

-

Enhanced mechanical durability – no fragile pins to bend or break

-

Improved thermal and electrical performance – essential for high-speed systems

-

Minimal maintenance requirements

-

Excellent compatibility with high-efficiency system designs

ACME PCB: Decades of Experience in BGA Assembly

At ACME Printed Circuit Board Assembly, we’ve offered BGA assembly and rework services since 1994. With advanced X-ray inspection systems and IPC-compliant processes, we provide precision BGA assembly on boards up to 65mm² and up to 36 layers.

Whether you need a production run or BGA prototype assembly, we can accommodate your needs—with or without stencils—to help reduce prototyping costs and accelerate development.

We are an ISO 9001:2015-certified electronics contract manufacturer located in Southern California, near the Los Angeles airport, specializing in small to medium PCB assembly runs. Our team adheres to IPC 610 workmanship standards and is committed to delivering consistent quality and high-yield BGA assemblies.

Need high-performance BGA assembly backed by decades of experience?

📞 Contact us today at 310-715-1898 or email us for more information.

BGA (Ball Grid Array) is a surface-mount packaging technology that enhances electrical and thermal performance in PCBs. Unlike traditional dual in-line or quad flat packages, BGA uses an array of solder balls beneath the component rather than protruding pins. These solder balls establish electrical connections to the PCB, offering better heat dissipation, signal integrity, and mechanical stability.

BGA (Ball Grid Array) is a surface-mount packaging technology that enhances electrical and thermal performance in PCBs. Unlike traditional dual in-line or quad flat packages, BGA uses an array of solder balls beneath the component rather than protruding pins. These solder balls establish electrical connections to the PCB, offering better heat dissipation, signal integrity, and mechanical stability. While BGA Assembly offers numerous benefits, ensuring flawless soldering and defect-free connections is crucial. Advanced techniques like X-ray inspection and reflow soldering help detect hidden defects and guarantee the highest level of precision.

While BGA Assembly offers numerous benefits, ensuring flawless soldering and defect-free connections is crucial. Advanced techniques like X-ray inspection and reflow soldering help detect hidden defects and guarantee the highest level of precision.