In the world of modern electronics, achieving optimal performance, reliability, and miniaturization is essential. Ball Grid Array (BGA) Assembly has emerged as a key technology in printed circuit board (PCB) manufacturing, enabling high-speed performance and superior durability. As industries continue to push for more compact and efficient devices, BGA Assembly plays a critical role in ensuring electronic components meet rigorous demands.

What Is BGA Assembly?

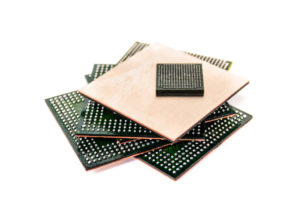

BGA (Ball Grid Array) is a surface-mount packaging technology that enhances electrical and thermal performance in PCBs. Unlike traditional dual in-line or quad flat packages, BGA uses an array of solder balls beneath the component rather than protruding pins. These solder balls establish electrical connections to the PCB, offering better heat dissipation, signal integrity, and mechanical stability.

BGA (Ball Grid Array) is a surface-mount packaging technology that enhances electrical and thermal performance in PCBs. Unlike traditional dual in-line or quad flat packages, BGA uses an array of solder balls beneath the component rather than protruding pins. These solder balls establish electrical connections to the PCB, offering better heat dissipation, signal integrity, and mechanical stability.

Key Advantages of BGA Assembly

1. Higher Performance and Reliability

With shorter electrical pathways, BGA assembly improves signal transmission speeds and reduces interference. This design ensures lower inductance and resistance, making it ideal for high-frequency applications such as processors, graphics cards, and networking devices.

2. Better Heat Dissipation

Excessive heat is a major concern in compact electronic devices. The BGA package efficiently dissipates heat due to its larger contact area and direct connection to the PCB. This improved thermal performance extends the lifespan of components, reducing the risk of overheating failures.

3. Enhanced Miniaturization

Modern electronics demand smaller yet more powerful components. BGA Assembly allows for higher pin counts in a compact space, enabling manufacturers to fit more functionality into smaller devices. This is crucial in mobile phones, wearables, and high-performance computing systems.

4. Stronger Mechanical Connections

Unlike traditional leaded packages, BGA solder joints are less prone to mechanical stress and vibration-related failures. The spherical solder connections provide better adhesion, enhancing the overall durability of the PCB.

Applications of BGA Assembly in Modern Electronics

BGA technology is widely used across various industries, including:

- Consumer Electronics – Smartphones, tablets, laptops, and gaming consoles rely on BGA packaging for their processors and memory chips.

- Automotive Electronics – Advanced driver-assistance systems (ADAS) and infotainment systems benefit from BGA’s superior reliability in harsh conditions.

- Medical Devices – Wearable health monitors and imaging equipment require compact and high-performance PCBs.

- Telecommunications & Networking – Routers, 5G infrastructure, and high-speed networking equipment utilize BGA Assembly for improved signal integrity.

Ensuring Quality in BGA Assembly

While BGA Assembly offers numerous benefits, ensuring flawless soldering and defect-free connections is crucial. Advanced techniques like X-ray inspection and reflow soldering help detect hidden defects and guarantee the highest level of precision.

While BGA Assembly offers numerous benefits, ensuring flawless soldering and defect-free connections is crucial. Advanced techniques like X-ray inspection and reflow soldering help detect hidden defects and guarantee the highest level of precision.

At Board Assembly, we specialize in high-quality BGA Assembly with state-of-the-art manufacturing techniques. Whether you need custom PCB solutions, rework services, or advanced testing, our expert team ensures reliable and high-performance electronic assemblies.

As electronics continue to evolve, BGA Assembly remains a critical technology for improving performance, efficiency, and reliability. By offering better heat dissipation, superior signal integrity, and enhanced miniaturization, BGA technology is shaping the future of high-performance devices.

To learn more about our BGA Assembly services, visit Board Assembly’s BGA Assembly page and discover how we can optimize your electronic designs.