-

When it comes to bringing an electronic product to market, every component matters—especially the printed circuit board (PCB). At Board Assembly, we specialize in PCB assembly solutions tailored to meet the unique demands of both small and large volume orders. Whether you’re a startup developing your first prototype or an established manufacturer scaling production, having a trusted assembly partner makes all the difference. Flexible PCB Assembly for Every Project Size Not all projects are created

-

When it comes to electronic products, the materials you choose for your printed circuit board (PCB) can make all the difference in performance, reliability, and even cost. Selecting the right PCB material isn’t just about picking what’s readily available; it’s about matching the material’s properties to your specific application. At Board Assembly, we understand the importance of PCB material selection and are here to help you navigate the options. Why PCB Material Matters Your PCB

-

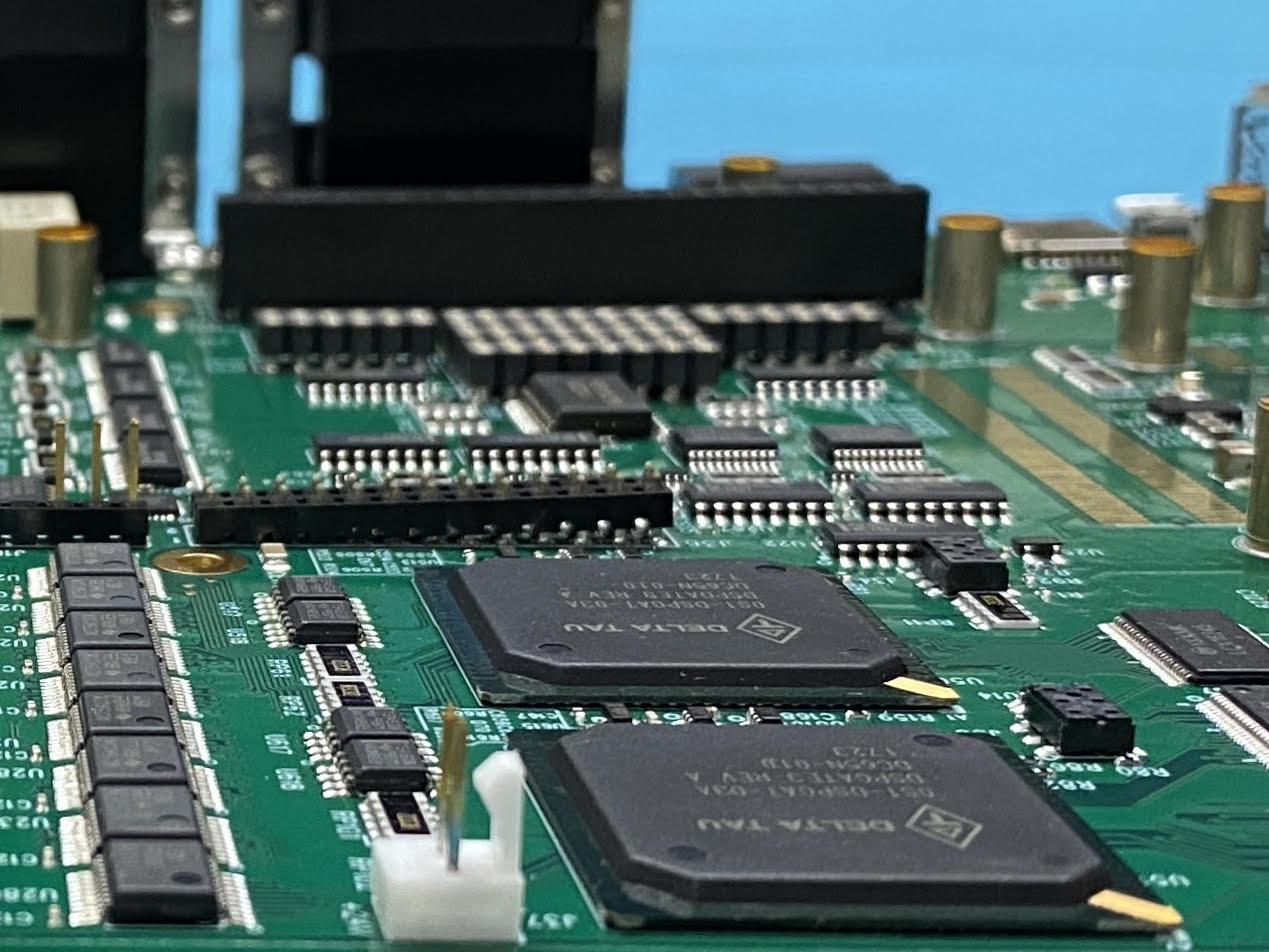

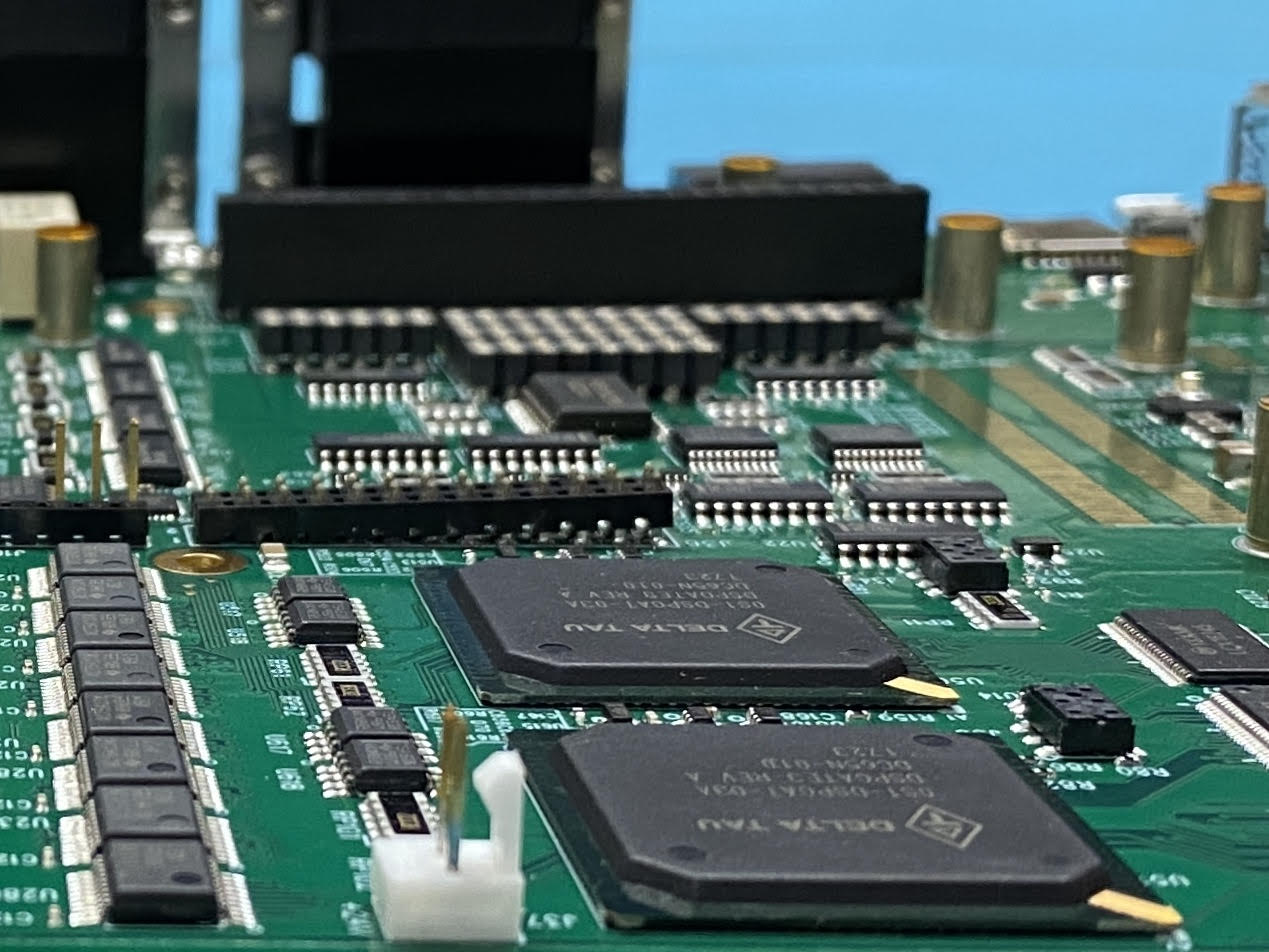

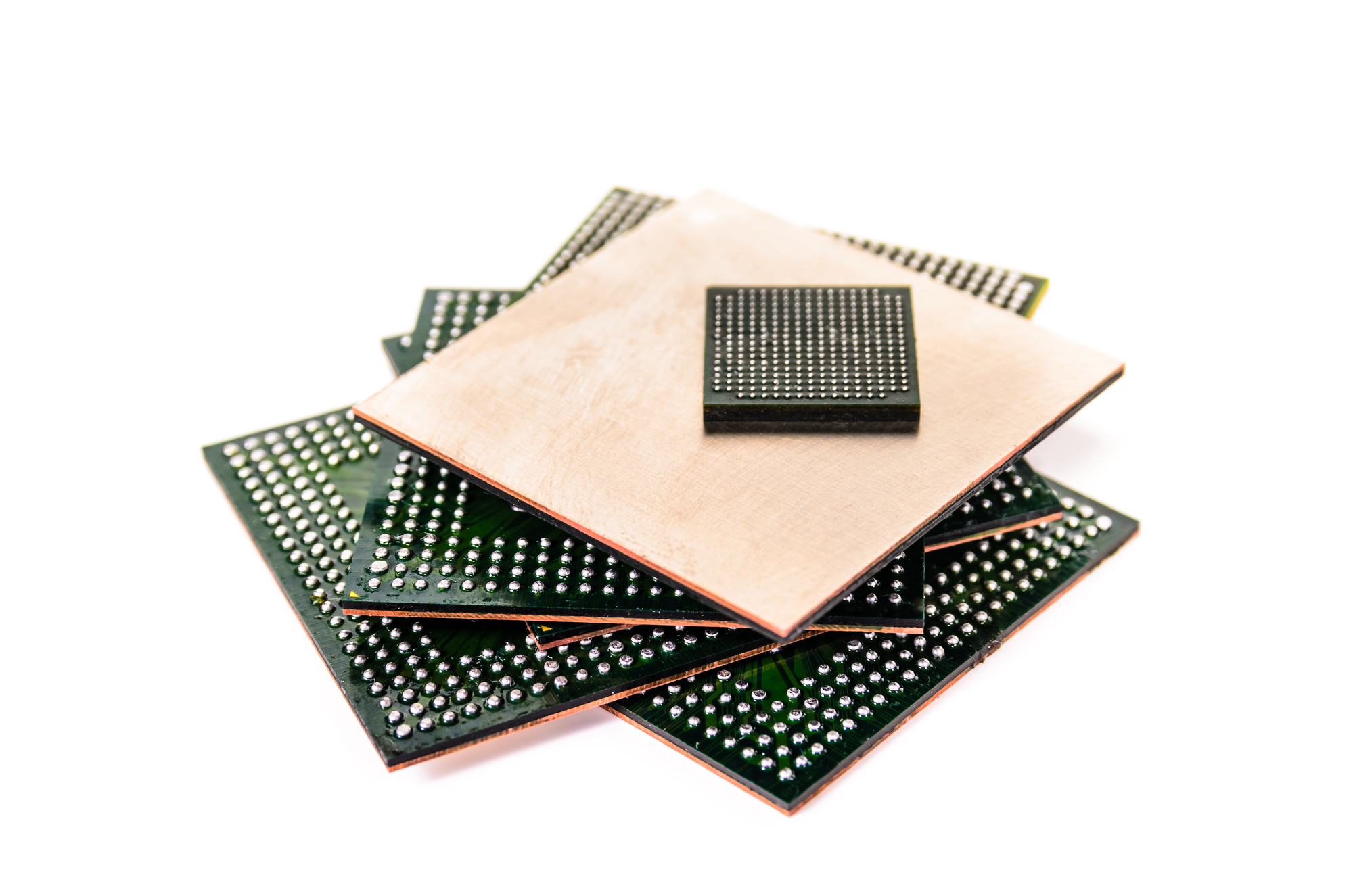

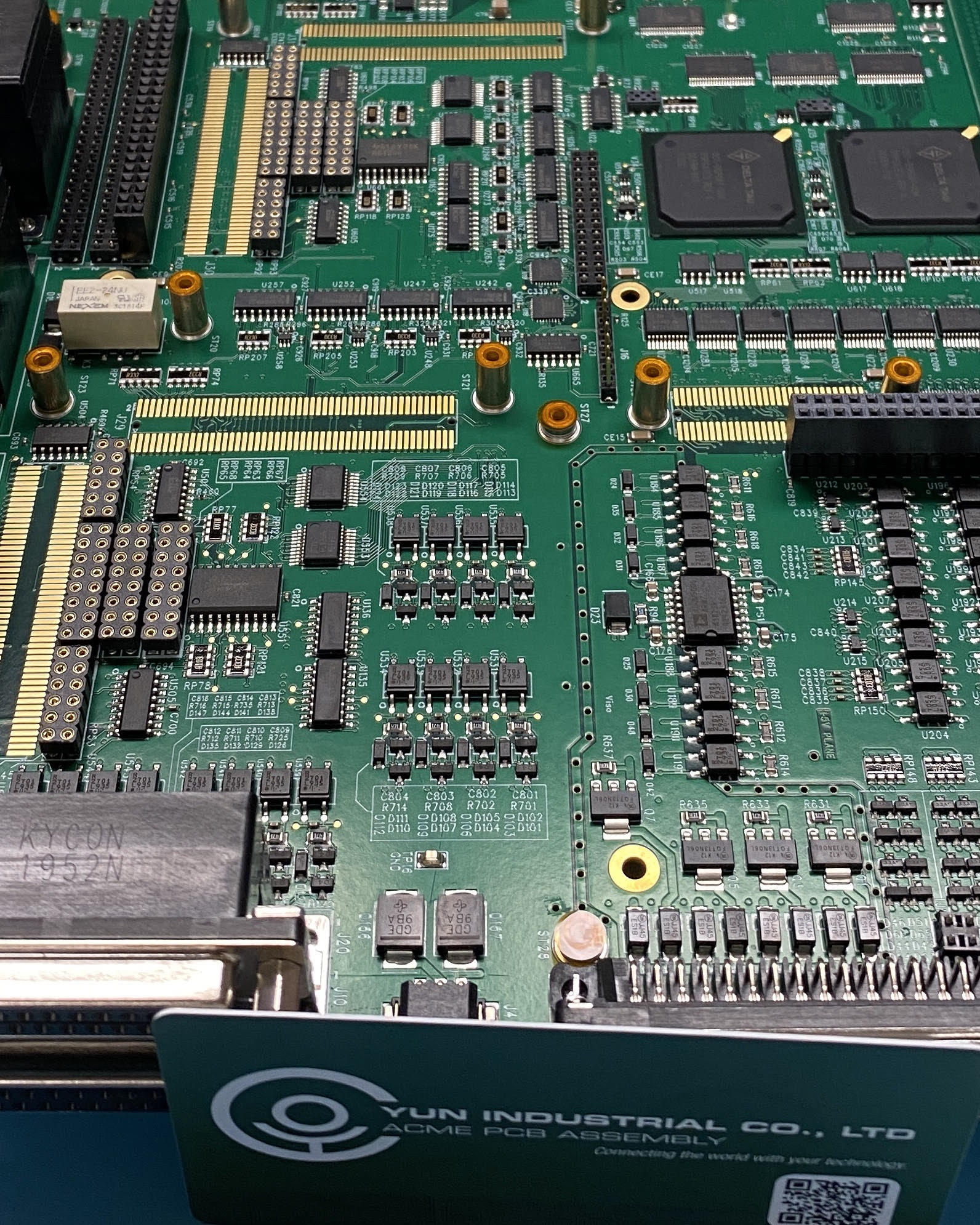

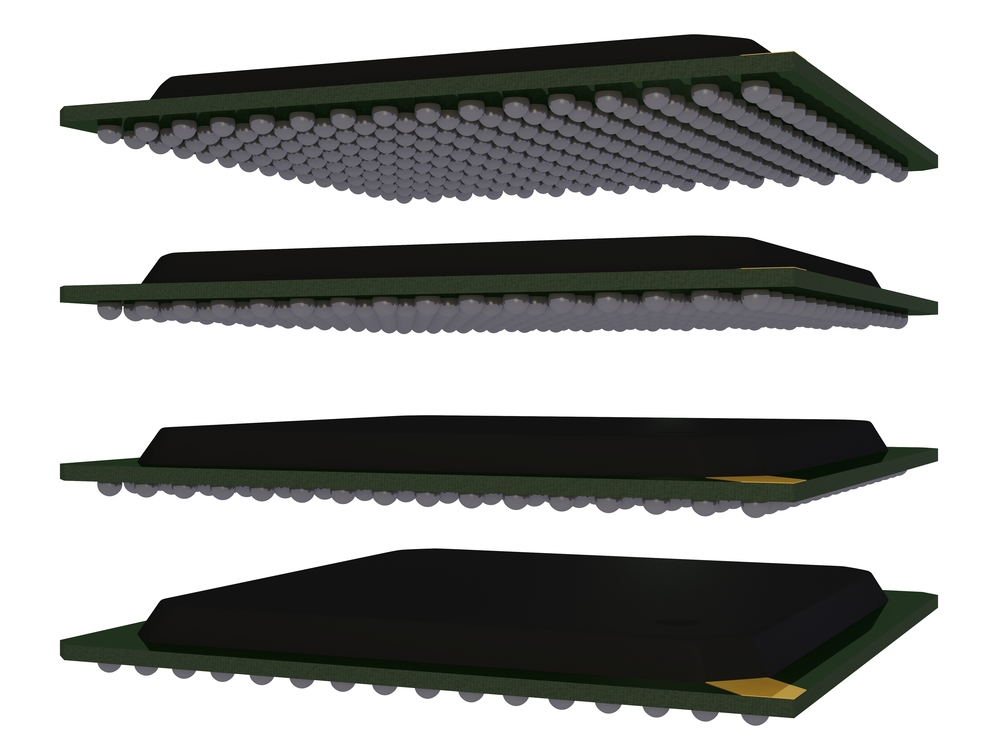

ACME PCB Assembly has provided (Ball Grid Array) BGA assembly, BGA rework, and BGA reballing service for Printed Circuit Boards since 1994. Having 20+ years experience behind us, we have extensive knowledge on how to assemble high quality (Ball Grid Array) BGAs. We have experience with everything from Micro BGAs to large size BGAs (55 mm), and ceramic BGAs to plastic BGAs. BGA assembly is a type of SMT process, which is used for Printed

-

For many entrepreneurs and manufacturers, traditional methods of electronics and printed circuit board (PCB) manufacturing can seem intimidating. Legacy manufacturing is often slow, error-prone, and expensive, which makes it difficult to move from concept to finished product. Historically, electronic assembly was designed for large batch runs and long lead times, leaving smaller orders and prototypes in a bind. Today, however, turnkey PCB assembly has revolutionized the industry, making it faster, easier, and more cost-effective for

-

Package-on-Package (PoP) is a type of IC packaging method that combines ball grid array (BGA) packages. In this method, two or more packages are vertically installed (i.e. stacked) with an interface that can direct signals between them. There are two popular configurations for PoP assemblies: Pure Memory Stacking: multiple memory packages are stacked on each other Mixed Logic-Memory Stacking: a memory package is stacked on top of a CPU package The packages are stacked on