-

In the ever-evolving world of electronics manufacturing, choosing the right assembly method is crucial for optimizing both performance and cost-efficiency. Two prominent techniques in this realm are Surface Mount Technology (SMT) and Through-Hole Technology. Each has its own advantages and drawbacks, making it essential to understand their unique characteristics and applications. Surface Mount Technology (SMT) has become the industry standard due to its efficiency and versatility. SMT involves mounting electronic components directly onto the surface

-

If you are in need of fully assembled printed circuit boards (PCBs) for your products, but you don’t know where to start, this article will guide you in the right direction. If you don’t have any printed circuit boards or any of the parts, and you certainly don’t want to burden your limited staff with the task of putting all those PCBs together, you will need a full-service PCB assembly provider. ACME PCB Assembly is

-

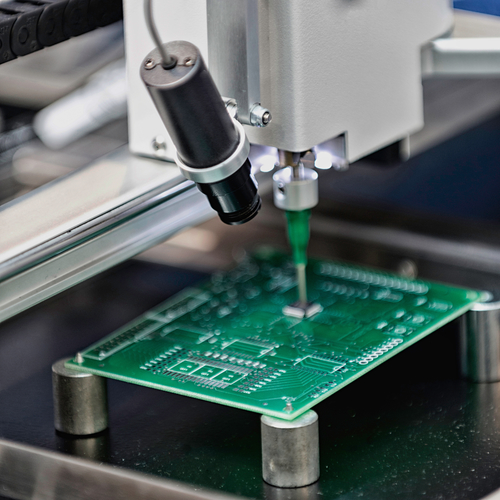

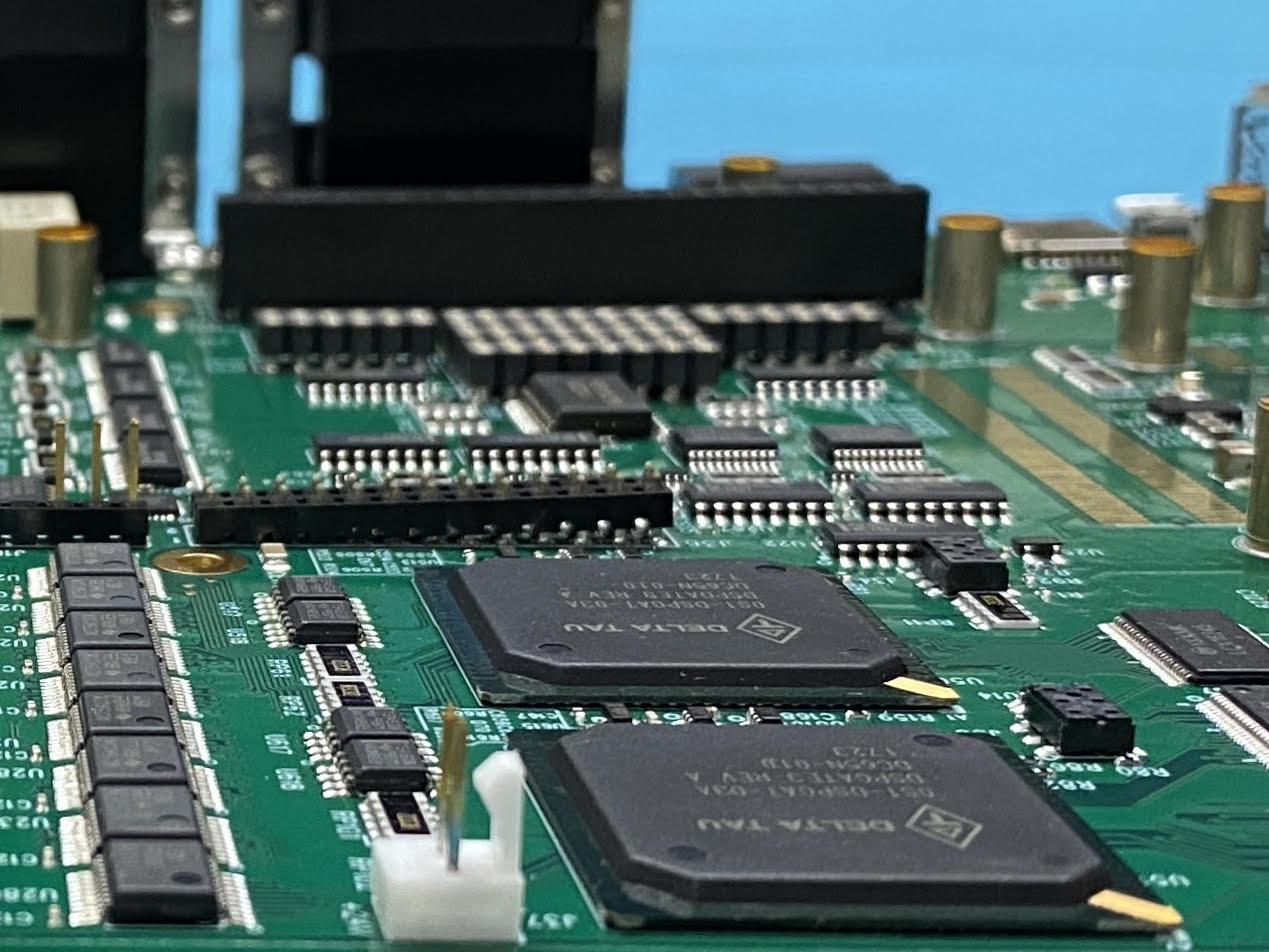

Printed Circuit Boards (PCBs) are the backbone of modern electronics, found in everything from smartphones to medical devices. At Board Assembly, we pride ourselves on our comprehensive PCB manufacturing process, which ensures top-quality products for a wide range of industries. In this blog, we’ll walk you through the PCB manufacturing process, from initial design to the final product. 1. Design and Layout The PCB manufacturing journey begins with the design phase. Engineers use specialized software

-

Differences Between Full Turn Key and Partial Turn Key Printed Circuit Board Services You are looking for a printed circuit board turn-key assembly provider for a new product. When you call up a printed circuit board manufacturer, the first question you are likely to get is, “Do you want full turn key service or partial turn key service?” What is the difference between full and partial turn key service, and what is the best option

-

Perhaps the greatest reliability issue to come out of the Restriction of Hazardous Substances (RoHS) Directive is tin whiskers. This residual effect of RoHS is nothing new to electronics manufacturing. Tin whiskers were first been reported in the 1940s and credited with taking down satellites and military planes, causing critical failures to pacemakers and space shuttle systems and even the shutdown of a nuclear power facility. Tin whiskers cause their fair share of headaches, but