ACME PCB Assembly offers a variety of low pressure molding solutions from design to production. We will safely encapsulate your electronics to provide a water tight solution by injecting engineered adhesives around electronic assemblies, delicate wires, and connector sealing. ACME PCB Assembly offers a collaborative design in engineering and prototyping.

ACME PCB Assembly offers a variety of low pressure molding solutions from design to production. We will safely encapsulate your electronics to provide a water tight solution by injecting engineered adhesives around electronic assemblies, delicate wires, and connector sealing. ACME PCB Assembly offers a collaborative design in engineering and prototyping.

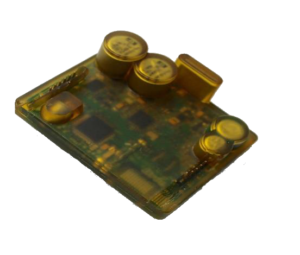

After we install the electronic components on your PCB products we can then add a water resistant coating, available in silicone’s, polyurethanes and acrylics. This type of service is better known as potting service or encapsulating. Potting acts as an excellent barrier against moisture, dust and most environmental contaminants.

Low Pressure Injection Molding

Low Pressure Injection Molding

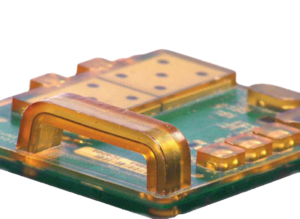

Low Pressure Injection Molding is cost effective for your company, it is an environmentally friendly process to encapsulate and protect components from the environment, including PCBs, sensors, switches, batteries, connectors, etc. ACME PCB Assembly offers low pressure molding, which is an environmentally friendly process that is positioned between potting and injection molding technologies.

Why Low Pressure Molding?

Low pressure molding offers a precise design allowing for more space and flexibility within the final assembled product, as well as, allowing for design capabilities beyond the form fit function of traditional materials. Skylining allows for the use of less material, which creates a precise encapsulation for a lighter weighing product.

Types of Low Pressure Molding

Electronic Encapsulation & Impact Resistance

This is a great cost-saving solution that will eliminate the need for a housing, it reduces capital investment costs, provides quick cycle times and protects fragile components.

Wire Harness Strain Relief

Low Pressure Molding is the chosen method to protect delicate fine-pitch connector assemblies. It also can provide strain relief within the same application. The process is flexible and requires low capital investment.

LED Lighting

Low Pressure Molding provides environmental protection from dust, moisture and vibration, and adheres to LED lenses. Molding can be done with the LED lens exposed or completely encapsulated.

Micro Switch & Sensor

Molding switches can be challenging because of the small size and thin, delicate side walls. Low Pressure Molding reduces complexity by removing the two-component thermoset curing process.

Mobile Battery

Low Pressure Molding reduces failure rates compared to traditional potting, particularly critical in the mobile phone battery industry.

Wire Connectors & Splicing

Low Pressure Molding offers huge benefits to the connector industry because of the low molding pressures.